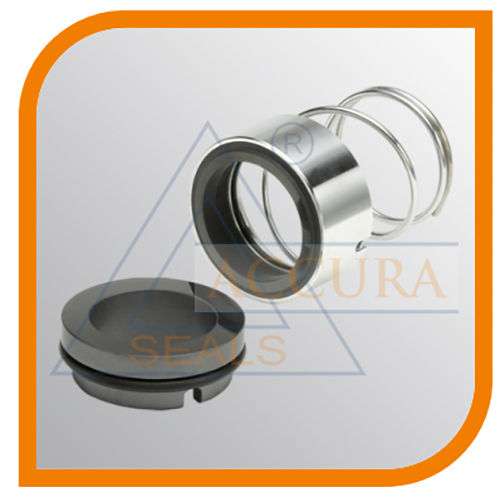

AS60DIN single seal

AS60DIN single seal Specification

- Hardness

- 85 Shore A

- Feature

- High chemical resistance, Easy installation, Leak-proof sealing

- Tolerance

- 0.02 mm

- Material

- EPDM/Ethylene Propylene Diene Monomer

- Style

- Single Seal

- Shape

- Round/O-Ring

- Temperature

- -30C to +120C

- Application

- DIN Standard Fittings, Hygienic and Sanitary Processing

- Compliance

- Meets food-grade and Phthalate-free requirements

- Profile

- Flat and profile gaskets available

- Color

- Black

- Service Life

- Long life, suitable for repetitive use

- Finish

- Smooth Surface

- Pressure

- Up to 10 bar

- Packing

- Individually packed for hygiene

- Standard

- DIN 11851

- Size Range

- DN10 to DN150

About AS60DIN single seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

- d1= 10 to 140 mm

- p= 10 kg/cm²

- v= 20 m/s

- t= -20 to +200ºC (*)

Types: AS61 and AS61 DIN: Secondary seals made of PTFE and contact surfaces in GB. AS60DIN: standardised models in accordance with EN 12756 NU.

Hygienic and Safe Sealing Solution

The AS60DIN single seal is meticulously designed to meet strict sanitary standards, providing optimal protection for food processing systems. Its phthalate-free and food-grade EPDM composition ensures safety without compromising durability. Additionally, individual packaging enhances hygiene, crucial for sensitive environments.

Reliable Performance and Longevity

With a hardness of 85 Shore A and precise tolerance of 0.02 mm, this seal guarantees reliable, repetitive performance even under demanding conditions. Its resistance to harsh chemicals and temperature fluctuations makes it suitable for robust applications, contributing to an extended service life and lower maintenance requirements.

FAQ's of AS60DIN single seal:

Q: How is the AS60DIN single seal installed in DIN Standard Fittings?

A: The AS60DIN single seal is designed for easy installation. Simply seat the round or O-Ring seal into the groove of your DIN 11851 fitting, ensuring its smooth surface faces outward. Its flexibility and accurate tolerance provide a snug fit and leak-proof performance.Q: What are the benefits of using EPDM material in the AS60DIN seal?

A: EPDM material offers superior chemical resistance, longevity, and flexibility across a wide temperature range (-30C to +120C). It also complies with food-grade and phthalate-free requirements, making it safe for hygienic and sanitary processing environments.Q: When should I replace the AS60DIN single seal?

A: Replace the seal if you notice visible damage, loss of elasticity, or persistent leaks after prolonged use. Due to its robust design and material, the AS60DIN seal has an extended service life and is suitable for repetitive applications, minimizing replacement frequency.Q: Where can the AS60DIN single seal be used?

A: It is ideal for applications requiring DIN Standard Fittings, especially in hygienic and sanitary processing industries such as food, beverage, and pharmaceuticals. Its versatile size range allows use across various equipment in Indian manufacturing and processing plants.Q: What is the packing process for the AS60DIN seal to ensure hygiene?

A: Each AS60DIN single seal is individually packed to prevent contamination during storage and handling. This packaging maintains cleanliness, supporting hygiene protocols required in food and pharmaceutical processing.Q: How does the AS60DIN seal maintain leak-proof performance under pressure?

A: Its precise tolerance of 0.02 mm, combined with a robust hardness and flexible EPDM material, allows the seal to form a reliable barrier against leaks. It is rated for use in pressures up to 10 bar, ensuring secure sealing even in demanding operational environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AS18B mechanical seal

Hardness : High hardness for superior wear resistance

Shape : Round

Temperature : 20C to +180C

Material : Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

Application : Water pumps, chemical pumps, oil pumps, centrifugal pumps

Tolerance : 0.01 mm

AFH - AFHC Seal

Hardness : 705 Shore A

Shape : Round

Temperature : 30C to +100C

Material : NBR (Nitrile Rubber)

Application : Hydraulic and pneumatic systems

Tolerance : 0.05 mm

AMB85 Seal

Hardness : 85 Shore A

Shape : Round

Temperature : 30C to +100C

Material : Nitrile Rubber (NBR)

Application : Hydraulic and Pneumatic Systems

Tolerance : 0.05 mm

AMB86 Seal

Hardness : 70 Shore A

Shape : Round

Temperature : 20C to +100C

Material : Nitrile Rubber (NBR)

Application : Automotive and Industrial Equipment

Tolerance : 0.1 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS