AMB85 Seal

AMB85 Seal Specification

- Hardness

- 85 Shore A

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR)

- Style

- Hydraulic Rod Seal

- Shape

- Round

- Temperature

- -30C to +100C

- Application

- Hydraulic and Pneumatic Systems

- Inner Diameter

- Varies (custom sizes available)

- Manufacturing Process

- Molded

- Pressure Resistance

- Up to 250 bar

- Thickness

- Standard or custom as required

- Color

- Black

- Installation

- Press-fit or snap-fit

- Outer Diameter

- Varies (custom sizes available)

- Chemical Resistance

- Good resistance to oils and hydraulic fluids

About AMB85 Seal

CHARACTERISTICS:

- Balanced.

- Welded metal bellows.

- Not dependent on the rotation direction.

OPERATING LIMITS -

- d1= 16 to 100 mm

- p= 20 kg/cm²

- v= 25 m/s

- t= -40 to +200ºC (*)

- -40 to +200 °C (up to 400º C with a special design) (*)

*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

Internally balanced, with no need for a stepped shaft (models AWS10B, AMS20B). The O-ring resting on the shaft does not cause wear as there is no axial movement. Appropriate for applications with sticky or high viscosity fluids as its open leaf design generates a self-cleaning effect. In addition it is suitable for application at moderate pressures and high temperatures (for up to 400º C please enquire) and very aggressive fluids in chemical and mechanical terms. Very often used in compressors.

Custom Sizing for Precise Applications

AMB85 Seals are available in a range of inner and outer diameters with customizable thickness to precisely meet your equipments requirements. Whether youre replacing an existing seal or need a unique size for new machinery, these seals can be tailored to your exact specifications, ensuring optimal compatibility and reliability in use.

Engineered for Hydraulic and Pneumatic Systems

Specifically designed for high-performance hydraulic and pneumatic systems, the AMB85 Seal provides robust sealing even in harsh environments. Its superior pressure resistance (up to 250 bar) and resistance to oils make it an ideal choice for preventing leaks and maintaining system efficiency.

High-Quality and Durable Material

Manufactured from premium Nitrile Rubber (NBR), the AMB85 seal features exceptional mechanical properties. It remains flexible and effective in a broad temperature range from -30C to +100C, ensuring long service life even under frequent pressure cycling and exposure to hydraulic fluids.

FAQs of AMB85 Seal:

Q: How do I install the AMB85 Seal in my hydraulic system?

A: The AMB85 Seal can be installed using either a press-fit or snap-fit method, depending on your equipment design. Ensure the sealing groove is clean and properly sized. Gently press the seal into place, avoiding sharp tools that could damage the rubber. For snap-fit installations, insert the seal evenly to avoid twisting.Q: What benefits does the AMB85 Seal offer for hydraulic and pneumatic applications?

A: AMB85 Seals deliver excellent resistance to oils and hydraulic fluids, high-pressure durability up to 250 bar, and adaptability to a wide temperature range. These features help maintain reliable system performance, prevent leaks, and reduce maintenance frequency.Q: When should I consider choosing a custom-sized AMB85 Seal?

A: Opt for a custom-sized AMB85 Seal when your application requires non-standard inner or outer diameters, or specific thicknesses not readily available. This ensures a perfect fit, improving sealing effectiveness and prolonging system life.Q: What materials are used in the manufacturing of the AMB85 Seal?

A: The AMB85 Seal is molded from Nitrile Rubber (NBR), providing enhanced chemical resistance, flexibility, and longevity. This material is chosen specifically for its superior performance in hydraulic and pneumatic systems.Q: Where are AMB85 Seals commonly used?

A: These seals are most commonly implemented in hydraulic and pneumatic devices across industrial machinery, construction equipment, and automotive systems due to their high-pressure resistance and durability.Q: What is the process for manufacturing an AMB85 Seal?

A: AMB85 Seals are produced through a precise molding process, allowing for consistent dimensional accuracy and repeatable quality. This manufacturing method enables the production of both standard and custom sizes to meet exact application needs.Q: How does the AMB85 Seals pressure and temperature resistance support its function?

A: With the capacity to withstand pressures up to 250 bar and temperatures ranging from -30C to +100C, the AMB85 Seal effectively prevents leakage and maintains performance even in intense operational conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

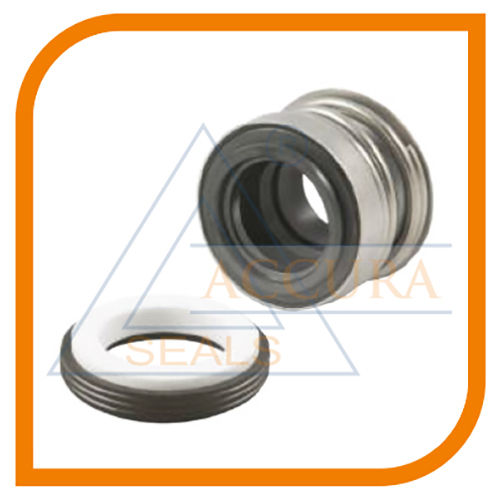

ARB05 Mechanical seal

Shape : Circular

Material : Carbon Stainless Steel

Style : Mechanical, Other

Application : Pumps

Temperature : Up to 200C

Hardness : High

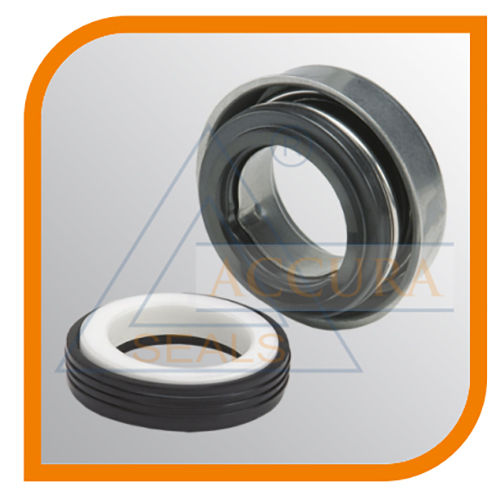

ATB16 mechanical seal

Shape : Circular

Material : Ceramic and stainless steel

Style : Mechanical Seal

Application : Pumps and rotary equipment

Temperature : Up to 200C

Hardness : High

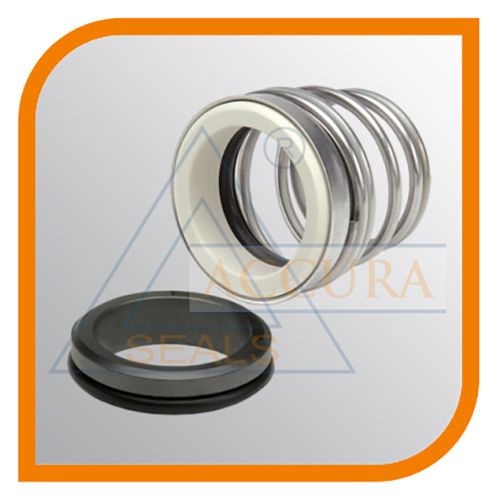

ARB03 - ARB03A - ARB03B Mechanical seal

Shape : Round

Material : Carbon Ceramic NBR

Style : Mechanical Seal

Application : Pump

Temperature : Up to 120C

Hardness : High

AS15 and AS15DIN all-purpose mechanical seal

Shape : Circular

Material : Steel Ceramic and Elastomer

Style : Compact coil spring mechanism, Other

Application : Allpurpose mechanical seal for various industrial applications

Temperature : Up to 200C

Hardness : Medium to High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS