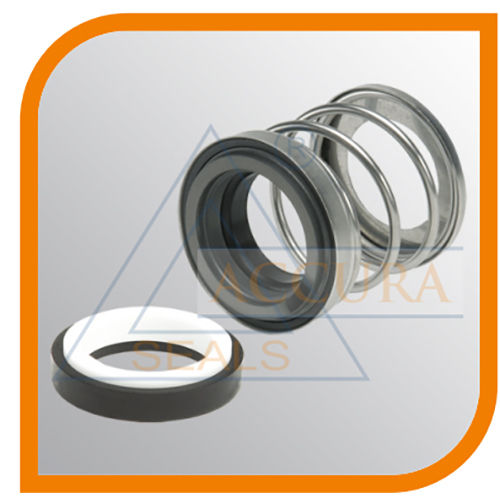

AMB86 Seal

AMB86 Seal Specification

- Tolerance

- 0.1 mm

- Hardness

- 70 Shore A

- Material

- Nitrile Rubber (NBR)

- Style

- Rotary Shaft Seal

- Shape

- Round

- Temperature

- -20C to +100C

- Application

- Automotive and Industrial Equipment

- Color

- Black

- Seal Type

- Rotary Shaft Seal

- Compression set

- Low

- Media Compatibility

- Oils, Water, Light Chemicals

- Installation

- Press Fit

- Pressure Rating

- Up to 10 bar

- Abrasion Resistance

- High

- Size

- Standard/Custom sizes available

About AMB86 Seal

CHARACTERISTICS:

- Balanced.

- Graphite wedge

- Not dependent on the rotation direction.

OPERATING LIMITS -

- d1= 25 to 100 mm

- p= 20 kg/cm²

- v= 25 m/s

- t= -75 to +425ºC (*)

Internally balanced, with no need for a stepped shaft (models AWS10B, AMS20B). The graphite wedge allwos applications at very high temperatures. Appropriate for applications with sticky or high viscosity fluids as its open leaf design generates a self cleaning effect. In addition it is suitable for application at moderate pressures as well as with very aggressive fluids, both chemically and mechanically terms. Very often used in compressors

Precision Engineering for Reliable Sealing

Designed to withstand harsh industrial and automotive environments, the AMB86 rotary shaft seal offers a secure, leak-proof barrier. With high abrasion resistance and low compression set, it maintains optimal performance over time. The precision tolerance of 0.1 mm ensures an exact fit, minimizing wear and maximizing seal life.

Versatile Compatibility and Easy Installation

Suitable for use with oils, water, and light chemicals, the AMB86 Seal adapts to a variety of applications. Its press-fit installation method saves time and labor, making maintenance straightforward. Available in both standard and custom sizes, this seal seamlessly integrates into diverse equipment.

FAQs of AMB86 Seal:

Q: How do I install the AMB86 Rotary Shaft Seal?

A: The AMB86 Seal is designed for simple press-fit installation. Ensure that the shaft and housing are clean and free from debris before gently pressing the seal into place. Use an appropriate tool to avoid damaging the seal or its surface.Q: What benefits does the use of Nitrile Rubber (NBR) provide for the AMB86 Seal?

A: Nitrile Rubber (NBR) offers excellent resistance to oils, water, and light chemicals, making the AMB86 ideal for both automotive and industrial environments. The material also provides high abrasion resistance and maintains its properties across a broad temperature range.Q: When should I consider using a custom-sized AMB86 Seal?

A: Custom-sized AMB86 Seals are recommended when your application requires unique dimensions for optimal fitment and sealing. This ensures reliable performance in specialized or non-standard equipment.Q: Where can the AMB86 Rotary Shaft Seal be used?

A: The AMB86 Seal is suitable for automotive and industrial equipment, particularly where rotary shafts require effective sealing against oils, water, or light chemicals under pressure up to 10 bar.Q: What is the recommended temperature range for using the AMB86 Seal?

A: The AMB86 Seal operates efficiently in temperature conditions from -20C to +100C, making it suitable for a wide range of climatological and operational environments.Q: How can I ensure correct tolerance during installation?

A: Refer to your equipments specifications to match the AMB86s 0.1 mm tolerance. Accurate alignment and careful pressing will help maintain the seals integrity and prevent leakage.Q: What process is used in manufacturing the AMB86 Seal?

A: AMB86 Seals are produced using high-quality NBR, shaped precisely to specification. Rigorous testing ensures compliance with hardness (70 Shore A), pressure, and dimensional tolerances, providing reliable sealing under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AFH - AFHC Seal

Application : Hydraulic and pneumatic systems

Tolerance : 0.05 mm

Hardness : 705 Shore A

Shape : Round

Temperature : 30C to +100C

Material : NBR (Nitrile Rubber)

AWS30 - AWS30A Seal

Application : Hydraulic Cylinders

Tolerance : 0.05 mm

Hardness : 80 5 Shore A

Shape : Round

Temperature : 30C to +100C

Material : Nitrile Rubber (NBR)

PNL Mechanical seal

Application : Pumps, Compressors, Mixers, Blowers

Tolerance : 0.05 mm

Hardness : 6070 Shore A

Shape : Round

Temperature : 20C to 180C

Material : Carbon, Ceramic, Stainless Steel, Nitrile Rubber

ARB01-ARB01S-ARB04-ARB04A and ARB06 Mechanical seal

Application : Pumps, Mixers and Agitators

Tolerance : 0.01 mm

Hardness : 6080 (Shore A)

Shape : Round

Temperature : 20C to +120C

Material : Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, Nitrile Rubber, Viton, EPDM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS