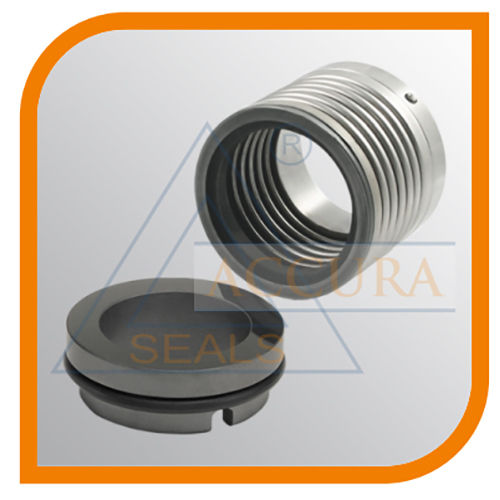

AFH - AFHC Seal

AFH - AFHC Seal Specification

- Feature

- Oil-resistant, Wear-resistant

- Tolerance

- 0.05 mm

- Hardness

- 705 Shore A

- Material

- NBR (Nitrile Rubber)

- Style

- AFH-AFHC

- Shape

- Round

- Temperature

- -30C to +100C

- Application

- Hydraulic and pneumatic systems

- Diameter Range

- 20 mm to 300 mm

- Compression Set

- Low

- Standard

- ISO 6194

- Elongation at Break

- 250%

- Thickness

- 3 mm to 10 mm

- Color

- Black

- Chemical Resistance

- Yes

About AFH - AFHC Seal

CHARACTERISTICS:

- Unbalanced.

- Single conical spring.

- Dependent on the rotation direction

- Exchangeable Contact Surfaces.

OPERATING LIMITS -

- d1= 10 to 100 mm

- p= 10 kg/cm

- v= 20 m/s

- t= -20 to +200C (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

A general-purpose single, robust seal in which the contact surfaces can be exchanged with each other. It can be used in industrial applications for clean fluids with low viscosities or with a low content of suspended solids that tend to produced sediments or adhere to the seal.Types: FH6: secondary seals made of PTFE. FHC: same structure as FH but the length is I3C.

Versatile Performance in Demanding Environments

Engineered for hydraulic and pneumatic applications, the AFH-AFHC Seal excels in conditions requiring robust chemical and oil resistance. Its functional temperature spectrum of -30C to +100C makes it suitable for diverse industrial setups, providing confidence in both low and high-temperature operations.

High-Quality NBR Material for Extended Durability

Constructed from premium Nitrile Rubber, this seal demonstrates remarkable resistance to oil, chemicals, and abrasion, making it a reliable choice for long-term use. The low compression set and high elongation at break ensure the seal maintains integrity, even after repeated cycles of use.

FAQ's of AFH - AFHC Seal:

Q: How is the AFH-AFHC Seal applied in hydraulic and pneumatic systems?

A: The AFH-AFHC Seal is installed at points where fluid leakage prevention is vital, typically within hydraulic cylinders or pneumatic valves. Its round shape and flexible NBR material ensure a tight, durable seal against moving parts.Q: What benefits does the low compression set provide for the AFH-AFHC Seal?

A: A low compression set means the seal retains its shape and elasticity even after long-term pressure, resulting in extended sealing performance and reduced maintenance frequency in industrial applications.Q: When should manufacturers choose an NBR seal with 705 Shore A hardness?

A: This hardness range strikes a balance between flexibility and strength, making the seal suitable for dynamic applications where both resilience to wear and firm pressure sealing are required-especially where oil resistance is paramount.Q: Where can the AFH-AFHC Seal be supplied or sourced in India?

A: The AFH-AFHC Seal is readily available through authorized manufacturers, retailers, and suppliers across India, ensuring easy procurement for industrial maintenance and OEM projects.Q: What is the process for ensuring chemical and oil resistance in this seal?

A: During manufacturing, the NBR (Nitrile Rubber) compound is specifically formulated and tested according to ISO 6194 to deliver superior resistance to a variety of chemicals and oils, ideal for harsh hydraulic environments.Q: How does the tolerance of 0.05 mm impact the usage of the seal?

A: The precise tolerance ensures a consistent fit in equipment, minimizing installation errors and enhancing sealing reliability, regardless of the application's size within the specified range.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

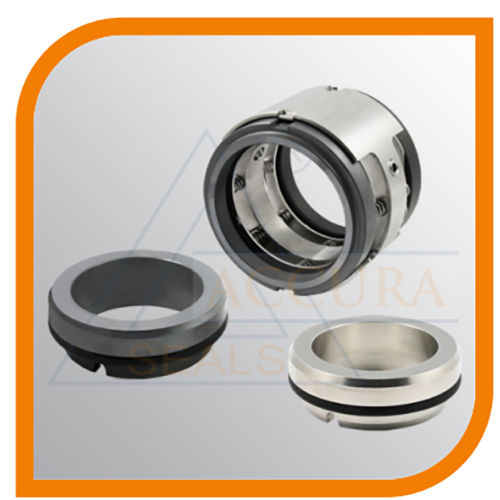

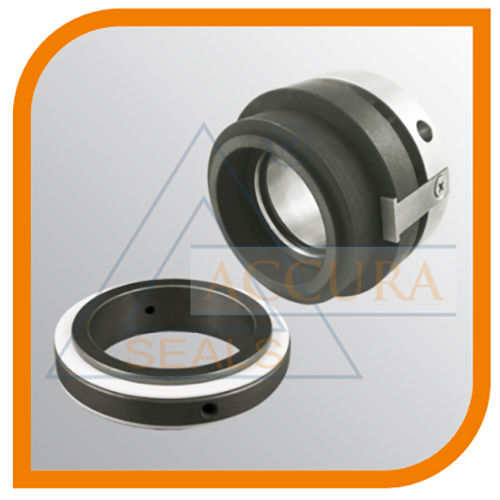

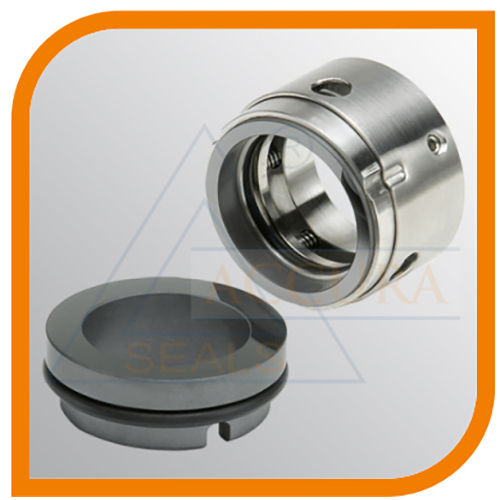

More Products in Mechanical Seals Category

AMB84 Seal

Application : Hydraulic cylinders, pneumatic cylinders, valves

Style : Other, Hydraulic Rod Seal

Shape : Round

Material : Nitrile Rubber (NBR)

Temperature : 30C to +120C

Hardness : 60 90 Shore A

AMS10D Double seal

Application : Hydraulic Cylinders, Pneumatic Systems

Style : Other, Double Seal

Shape : Round

Material : Nitrile Rubber (NBR)

Temperature : 20C to +100C

Hardness : 70 Shore A

AMS28 Seal

Application : Hydraulic Cylinders

Style : Other, Hydraulic Rod Seal

Shape : Round

Material : Nitrile Rubber (NBR)

Temperature : 30C to +110C

Hardness : 855 Shore A

AMS11 Seal compliant

Application : Sealing for rotating equipment

Style : Mechanical Seal

Shape : Round

Material : Stainless Steel

Temperature : 0C to 250C

Hardness : Medium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS