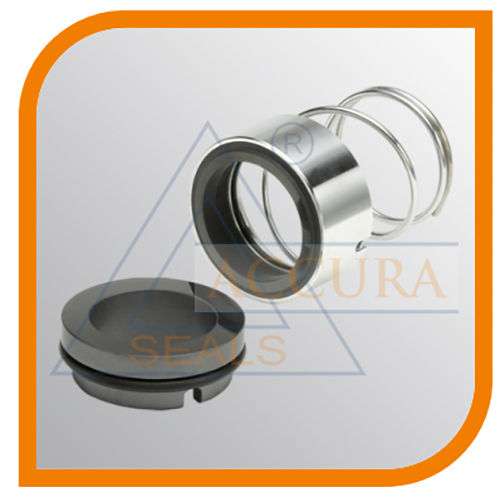

AS18B mechanical seal

AS18B mechanical seal Specification

- Feature

- Corrosion resistant; Easy to install; Long service life

- Hardness

- High hardness for superior wear resistance

- Tolerance

- 0.01 mm

- Material

- Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

- Style

- AS18B Single Spring

- Shape

- Round

- Temperature

- -20C to +180C

- Application

- Water pumps, chemical pumps, oil pumps, centrifugal pumps

- Rotation Direction

- Bi-directional

- Rotary Faces

- Carbon, Ceramic, Silicon Carbide

- Maximum Pressure

- Up to 2.5 MPa

- Dynamic Run-out

- 0.1 mm

- Shaft Size Range

- 10 mm to 50 mm

- Spring Material

- Stainless Steel AISI 304/316

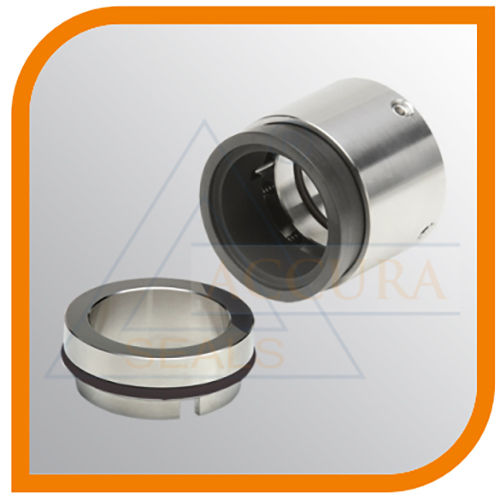

- Seal Type

- Balanced Mechanical Seal

- Suitable Medium

- Clean water, Oil, Light chemicals

- Stationary Faces

- Ceramic, Silicon Carbide

About AS18B mechanical seal

- Balanced.

- Single conical spring

- Dependent on the rotation direction.

- d1= 10 to 80 mm

- p= 25 kg/cm

- v= 15 m/s

- t=20 to 200 deg C

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

This mechanical seal has an extremely versatile and functional design and is suitable for working at pressures of up to 25 kg/cm . The rotating part of the seal can be combined with a large variety of stationary parts, which offers a wide range of combinations. Its structure allows secondary seals made of different materials to be used: FKM, Aflas, FFKM, FEP, NBR, HNBR and materials complying with special standards such as FDA, USP, EC 1935/2004, etc.

Exceptional Durability and Performance

The AS18B balanced mechanical seal is crafted with high-hardness components and precision tolerance to deliver superior wear resistance and extended operational longevity. Its robust construction withstands demanding conditions, making it a reliable choice for various fluid handling applications.

Versatile Compatibility

With a bi-directional design and suitability for clean water, oils, and light chemicals, the AS18B seal can be utilized across multiple pump types. It accommodates shaft sizes from 10 mm to 50 mm, ensuring broad compatibility with pumps in industrial and commercial environments.

Advanced Corrosion and Chemical Resistance

Key materials such as stainless steel (AISI 304/316), advanced ceramics, and elastomers like Viton or EPDM protect the seal from corrosive environments. The AS18B remains reliable and durable, even during exposure to aggressive media or fluctuating temperatures.

FAQ's of AS18B mechanical seal:

Q: How is the AS18B mechanical seal installed, and is it suitable for retrofitting existing pumps?

A: The AS18B mechanical seal features an easy-to-install design, compatible with standard round shaft configurations and sizes from 10 mm to 50 mm. Its single-spring, balanced construction makes it ideal for both new equipment and retrofitting into existing pumps without extensive modifications.Q: What pump types and media are best suited for the AS18B seal?

A: The AS18B seal is designed for use in water pumps, chemical pumps, oil pumps, and centrifugal pumps. It is most effective with clean water, oils, and light chemicals, thanks to its corrosion resistance and broad material compatibility.Q: When should I choose a balanced mechanical seal like the AS18B for my application?

A: A balanced seal like the AS18B should be selected when dealing with higher pressures (up to 2.5 MPa), aggressive or variable media, or when long service life and reduced wear are critical. Its balanced design helps reduce the load on seal faces, preventing premature failure.Q: Where is the AS18B mechanical seal manufactured and available for purchase?

A: The AS18B mechanical seal is manufactured in India and is available through authorized manufacturers, retailers, and suppliers across the country.Q: What is the expected benefit of using high-hardness materials and tight tolerance in the AS18B?

A: Utilizing high-hardness materials such as silicon carbide and maintaining a tight manufacturing tolerance (0.01 mm) ensures exceptional wear resistance, greater sealing reliability, and extended seal life, even under demanding operational conditions.Q: How does the AS18B mechanical seal handle dynamic misalignment or run-out?

A: The AS18B mechanical seal accommodates dynamic run-out up to 0.1 mm. This capability helps maintain effective sealing performance even when slight shaft misalignments or vibrations are present in the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS14 Seal

Material : Nitrile Rubber (NBR)

Tolerance : 0.1 mm

Shape : Round

Style : Other, AMS14

Application : Hydraulic and pneumatic sealing

Temperature : 30C to +120C

AMS26 Balanced mechanical seal

Material : Carbon, Silicon Carbide, Stainless Steel, EPDM, Viton

Tolerance : 0.01 mm

Shape : Round

Style : Other, Balanced Mechanical Seal

Application : Pumps, Compressors, Mixers, Agitators

Temperature : 20C to 180C

AMB86 Seal

Material : Nitrile Rubber (NBR)

Tolerance : 0.1 mm

Shape : Round

Style : Other, Rotary Shaft Seal

Application : Automotive and Industrial Equipment

Temperature : 20C to +100C

AWS12 Seal

Material : Example Material

Tolerance : Example Tolerance

Shape : Example Shape

Style : Other, Example Style

Application : Example Application

Temperature : Example Temperature

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS