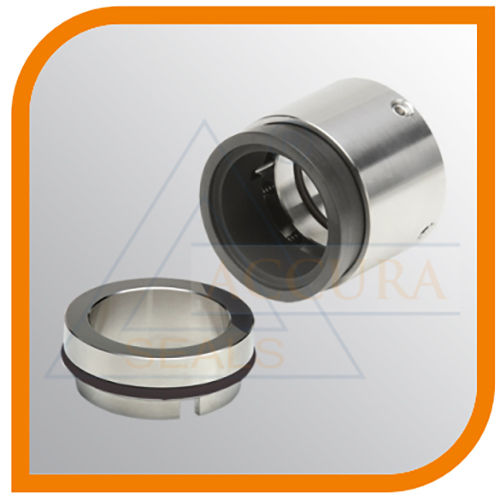

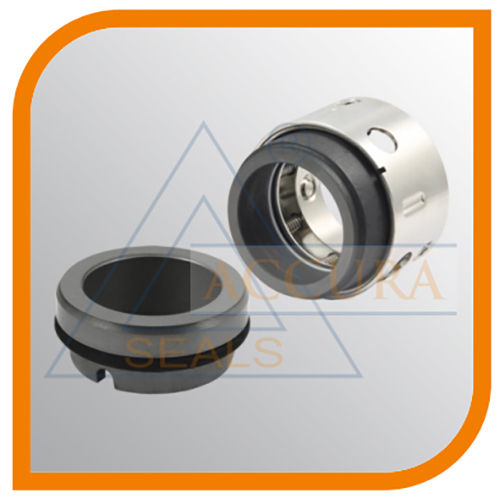

ARB50 balanced seal

ARB50 balanced seal Specification

- Hardness

- 60-80 Shore A

- Feature

- Balanced design, High pressure resistance, Low leakage

- Tolerance

- 0.05 mm

- Material

- Carbon, Ceramic, SS304, PTFE, Viton, Silicon Carbide

- Style

- Mechanical Seal

- Shape

- Round

- Temperature

- -20C to +200C

- Application

- Pumps, Mixers, Compressors

- Size Range

- 20 mm to 100 mm shaft diameter

- Seal Type

- Single Balanced

- Media Compatibility

- Water, Oil, Chemical, Slurry, Gases

- End Connections

- DIN, ISO, ANSI

- Rotational Speed

- Up to 3500 RPM

- Color

- Black/Silver

- Mounting Type

- Cartridge/Non-cartridge

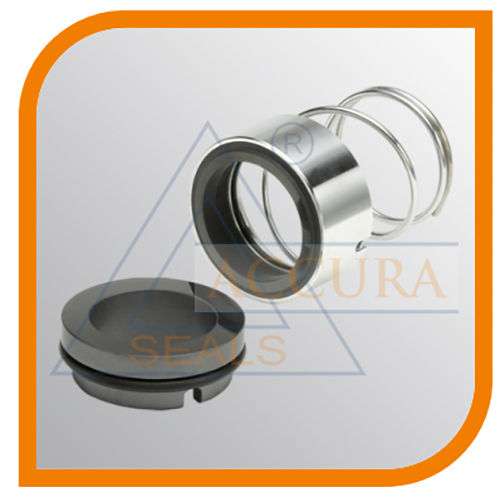

- Spring Type

- Multi-spring

- Pressure Rating

- Up to 25 bar

- Surface Finish

- Polished

About ARB50 balanced seal

CHARACTERISTICS:

- Balanced.

- Not dependent on the rotation direction

- Single cylindrical spring.

OPERATING LIMITS -

- d1=14 to 100 mm

- p= 20kg/cm²

- v= 15 m/s

- t= -15 to + 200ºC (*)

A balanced seal without the need for a stepped shaft. The casing of the rotating part protects the bellows from abrasion and from the rotation transmission tensions, and the spring from blocking in the event of being contaminated by fibers and particles. It is recommended for use with highly viscous or sticky fluids containing fibers or particles, or with fluids that produce a chemical attack on the shaft.

Versatile Industrial Seal for Demanding Applications

Engineered for reliability, the ARB50 balanced seal meets the rigorous needs of industries seeking media compatibility with water, oils, chemicals, slurry, and gases. Its round mechanical seal shape, robust construction, and flexible mounting options ensure seamless integration with pumps, mixers, and compressors operating in temperature extremes from -20C to +200C.

Superior Performance and Safety

With a high-quality polished surface finish, multi-spring design, and advanced material selection, the ARB50 seal offers exceptional durability and performance. Its balanced design minimizes leakage and wear, supporting process efficiency and ensuring safety under pressure ratings of up to 25 bar.

FAQ's of ARB50 balanced seal:

Q: How is the ARB50 balanced seal installed in pumps and mixers?

A: The ARB50 balanced seal can be installed using either cartridge or non-cartridge mounting methods, compatible with DIN, ISO, and ANSI end connections. Installation should follow manufacturer guidelines to ensure proper alignment and secure fit around shaft diameters ranging from 20 mm to 100 mm.Q: What media can the ARB50 balanced seal handle safely?

A: This seal is designed for compatibility with water, oil, chemicals, slurry, and gases, thanks to its durable material composition of carbon, ceramic, SS304, PTFE, Viton, and silicon carbide, making it a versatile choice for a wide array of industrial processes.Q: When should the ARB50 balanced seal be selected for a high-pressure application?

A: The ARB50 is recommended for operations demanding resistance to high pressures up to 25 bar, such as fluid handling in pumps, mixers, or compressors where process reliability and low leakage are critical to performance.Q: Where can these mechanical seals be sourced in India?

A: Manufacturers, retailers, and suppliers throughout India offer the ARB50 balanced seal. It is widely available for industrial procurement and can be sourced for both OEM and equipment maintenance needs.Q: What is the benefit of choosing the ARB50's multi-spring and balanced design?

A: The multi-spring configuration ensures consistent face loading, while the balanced design reduces seal face stress, achieving low leakage rates and longer operational life even under variable pressure and temperature conditions.Q: How does the precise tolerance of 0.05 mm contribute to seal performance?

A: Precise tolerance ensures optimal fit and alignment, reducing wear and minimizing leakage. This accuracy enhances the overall reliability and efficiency of the ARB50 seal in demanding industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS14 Seal

Shape : Round

Application : Hydraulic and pneumatic sealing

Material : Nitrile Rubber (NBR)

Style : Other, AMS14

Temperature : 30C to +120C

Hardness : 6090 Shore A

AMS20B - AMS20BT Seal

Shape : Round

Application : Rotating shaft sealing, hydraulic equipment

Material : Nitrile Rubber (NBR)

Style : Other, Lip Seal

Temperature : 30C to +100C

Hardness : 705 Shore A

AS18B mechanical seal

Shape : Round

Application : Water pumps, chemical pumps, oil pumps, centrifugal pumps

Material : Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

Style : Other, AS18B Single Spring

Temperature : 20C to +180C

Hardness : High hardness for superior wear resistance

AMS26 Balanced mechanical seal

Shape : Round

Application : Pumps, Compressors, Mixers, Agitators

Material : Carbon, Silicon Carbide, Stainless Steel, EPDM, Viton

Style : Other, Balanced Mechanical Seal

Temperature : 20C to 180C

Hardness : 60 to 70 HRC (Seal Faces)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS