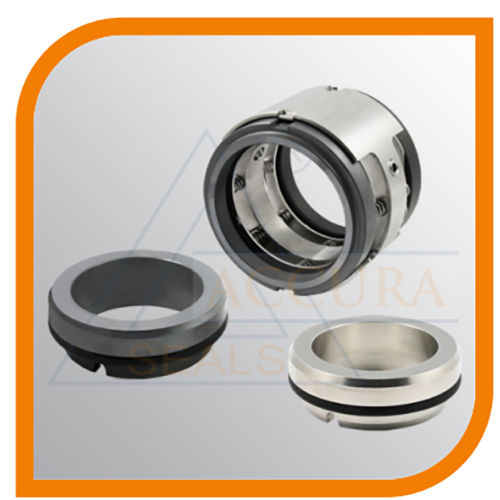

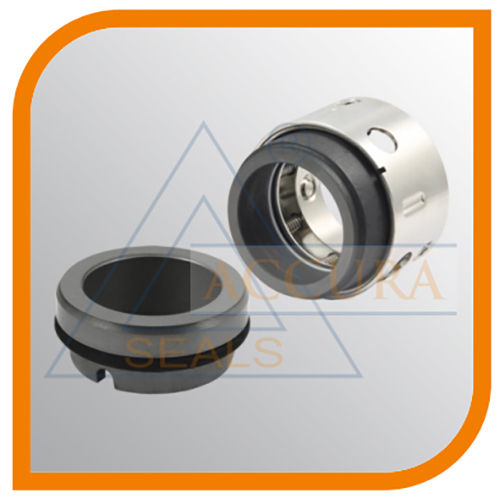

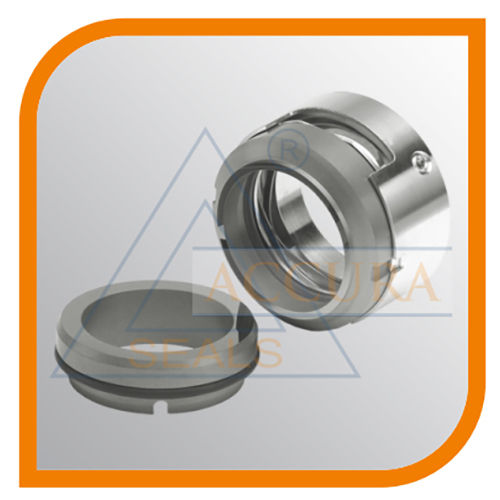

AMS26 Balanced mechanical seal

AMS26 Balanced mechanical seal Specification

- Hardness

- 60 to 70 HRC (Seal Faces)

- Tolerance

- 0.01 mm

- Material

- Carbon, Silicon Carbide, Stainless Steel, EPDM, Viton

- Style

- Balanced Mechanical Seal

- Shape

- Round

- Temperature

- -20C to 180C

- Application

- Pumps, Compressors, Mixers, Agitators

- Leakage Prevention

- Double Locking System

- Maintenance

- Easy to install and maintain

- Direction of Rotation

- Independent

- Pressure Range

- Up to 16 bar

- Corrosion Resistance

- High

- Shaft Diameter Range

- 12 mm to 100 mm

- Rotational Speed

- Up to 3000 RPM

- Secondary Seals

- Viton, PTFE, EPDM

- Face Combination

- Carbon vs Sic, Sic vs Sic, Ceramic vs Sic

- Design Features

- Single Spring, Rubber Bellow Design

About AMS26 Balanced mechanical seal

- Balanced.

- Independent Rotation System

- Multispring

- p = 50 kg/cm

- v= 50 m/s

- t= -20 to +140C (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

Balanced mechanical seal with protected springs to prevent them from blocking when in contact with sticky or viscous fluids. The O-ring on the shaft is static, thereby preventing fretting of the shaft.

Supreme Corrosion Resistance

Made from high-grade materials such as Carbon, Silicon Carbide, and Stainless Steel, the AMS26 Balanced Mechanical Seal delivers exceptional resistance to corrosive fluids. Its innovative design minimizes wear and extends service life, making it ideal for harsh industrial environments and critical applications.

Easy Installation and Maintenance

Designed for straightforward assembly, the AMS26 seal simplifies both installation and maintenance, saving operational downtime. Its balanced style and rubber bellow design allow for hassle-free fitting and adjustment, making it suitable for both new systems and as a replacement part.

Versatile Application Compatibility

Suitable for shaft diameters from 12 mm up to 100 mm, the AMS26 supports a wide range of pumps, mixers, compressors, and agitators. Its ability to handle temperatures between -20C to 180C, paired with high rotational speeds up to 3000 RPM, ensures versatility across many industrial processes.

FAQs of AMS26 Balanced mechanical seal:

Q: How does the AMS26 Balanced Mechanical Seal prevent leakage in demanding environments?

A: The AMS26 uses a double locking system in conjunction with a single spring and rubber bellow design to provide superior leakage prevention. This combination ensures reliable sealing under pressure up to 16 bar, even in corrosive and high-speed applications.Q: What are the primary benefits of the AMS26 seal for industrial users?

A: The AMS26 offers high corrosion resistance, easy installation and maintenance, tolerance precision (0.01 mm), and broad compatibility with various equipment. Its robust construction and selection of secondary seals (Viton, PTFE, EPDM) further enhance operational reliability and longevity.Q: When should I choose the AMS26 seal over other types?

A: The AMS26 is ideal when you require a balanced mechanical seal capable of handling pressures up to 16 bar, temperatures from -20C to 180C, and high rotational speeds. Its advanced materials and precise tolerance make it suitable for critical applications in pumps, agitators, and compressors.Q: Where can the AMS26 Balanced Mechanical Seal be effectively used?

A: This seal is designed for use in pumps, mixers, compressors, and agitators where consistent sealing, leak prevention, and resistance to corrosive media are vital. Its versatility also suits a wide spectrum of industrial sectors across India and globally.Q: What face material combinations are available for the AMS26 seal, and how does this affect performance?

A: AMS26 offers face combinations such as Carbon vs Sic, Sic vs Sic, and Ceramic vs Sic. These configurations allow users to match seal materials to process requirements, optimizing wear resistance, thermal stability, and compatibility with process fluids.Q: How is the installation and maintenance process managed for the AMS26 seal?

A: The AMS26 is engineered for simple installation and routine maintenance, thanks to its single spring and balanced round shape. Most procedures can be carried out without expert training, reducing downtime and maintenance costs for end-users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS10D Double seal

Temperature : 20C to +100C

Style : Other, Double Seal

Hardness : 70 Shore A

Tolerance : 0.05 mm

Material : Nitrile Rubber (NBR)

Shape : Round

AMS20B - AMS20BT Seal

Temperature : 30C to +100C

Style : Other, Lip Seal

Hardness : 705 Shore A

Tolerance : 0.02 mm

Material : Nitrile Rubber (NBR)

Shape : Round

AFH - AFHC Seal

Temperature : 30C to +100C

Style : Other, AFHAFHC

Hardness : 705 Shore A

Tolerance : 0.05 mm

Material : NBR (Nitrile Rubber)

Shape : Round

AWS10 single seal

Temperature : 20C to 180C

Style : Other, Single Spring Seal

Hardness : 6090 Shore A

Tolerance : 0.05 mm

Material : Carbon, Ceramic, Nitrile Rubber, Stainless Steel

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS