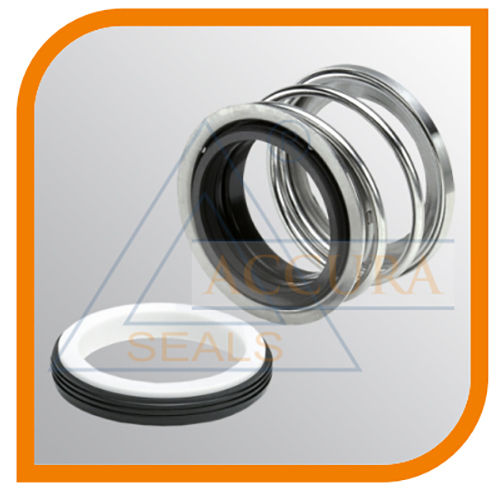

AMS14 Seal

AMS14 Seal Specification

- Tolerance

- 0.1 mm

- Hardness

- 60-90 Shore A

- Feature

- High wear resistance, oil and abrasion resistant

- Material

- Nitrile Rubber (NBR)

- Style

- AMS14

- Shape

- Round

- Temperature

- -30C to +120C

- Application

- Hydraulic and pneumatic sealing

- Pressure Resistance

- Up to 25 MPa

- Diameter

- 14 mm

- Color

- Black

- Elongation at Break

- >300%

About AMS14 Seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

OPERATING LIMITS -

- d1 = 18 to 100 mm

- p= 14 kg/cm²

- v= 15 m/s

- t= -15 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

Suitable for working in applications with high pres The springs are not in contact with the fluid. Ideal for working with particle-laden fluids in which standard designs tend to become blocked. Internally balanced, with no need for a stepped shaft sures. The O-ring resting on the shaft does not cause wear as there is no axial movement (changes in pressure).

Exceptional Pressure and Temperature Performance

The AMS14 Seal is designed to withstand harsh conditions, offering reliable resistance to pressures up to 25 MPa and operating efficiently within temperatures ranging from -30C to +120C. Its advanced NBR material ensures it maintains integrity in high-stress hydraulic and pneumatic environments.

Superior Material and Precision Engineering

Made from high-quality nitrile rubber, this seal boasts a remarkable elongation at break above 300% and a hardness range of 60-90 Shore A. The 0.1 mm tolerance guarantees a precise fit, contributing to extended service life and optimal performance in industrial applications.

Versatile Application Across Industries

Perfect for manufacturers, retailers, and suppliers in India, the AMS14 Seal excels in hydraulic and pneumatic sealing tasks. Its oil and abrasion resistance makes it suitable for use in demanding equipment, ensuring minimal leaks and reduced maintenance costs.

FAQ's of AMS14 Seal:

Q: How do I install the AMS14 Seal for hydraulic and pneumatic applications?

A: To install the AMS14 Seal, ensure the equipment surface is clean and free of debris. Gently place the seal into the designated groove, taking care not to overstretch or damage its edges. Its round shape and precise dimensions enable a snug fit without special tools.Q: What are the benefits of using Nitrile Rubber (NBR) in the AMS14 Seal?

A: Nitrile Rubber (NBR) offers outstanding resistance to oil and abrasives, making it ideal for hydraulic and pneumatic environments. Its high elongation and hardness ensure durability under variable pressure and temperature, reducing the risk of seal failure.Q: When should the AMS14 Seal be replaced in my equipment?

A: Replace the AMS14 Seal when you notice visible wear, hardening, surface cracks, or persistent leaks. Routine inspections and timely replacement help maintain optimal sealing performance and prevent equipment downtime.Q: Where is the AMS14 Seal commonly used in industrial settings?

A: The AMS14 Seal is widely used in hydraulic cylinders, pneumatic actuators, pumps, and other systems requiring reliable fluid containment. Its versatility and robust performance make it a preferred choice in manufacturing facilities across India.Q: What process ensures the AMS14 Seal's precise tolerance and dimensions?

A: The AMS14 Seal is manufactured using advanced molding and quality control procedures, ensuring a tight tolerance of 0.1 mm. Each seal undergoes thorough inspection to guarantee consistency in fit and reliability for demanding applications.Q: How does the AMS14 Seal contribute to equipment longevity?

A: By providing high wear resistance and excellent oil and abrasion protection, the AMS14 Seal reduces the risk of leaks and premature component failure. Its durability helps minimize maintenance needs and extend the operational life of hydraulic and pneumatic systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

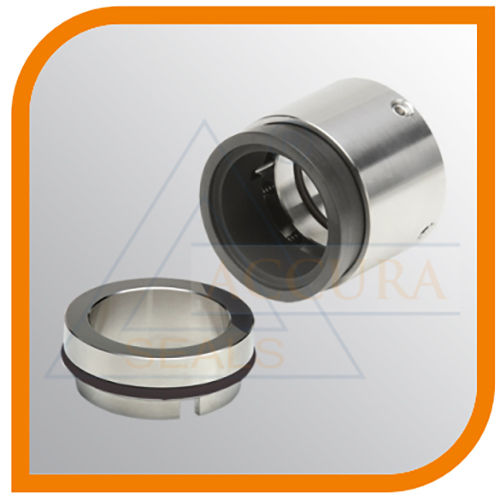

AMS13 Seal compliant

Style : Mechanical Seal

Tolerance : 0.05 mm

Temperature : 150C

Shape : Circular

Material : Stainless Steel

Application : Rotating Equipment

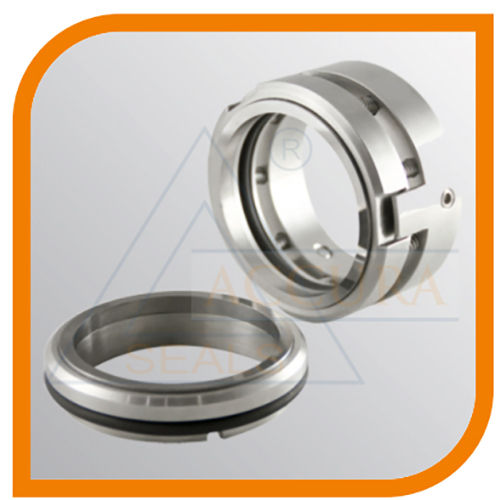

AMS27 multi-spring mechanical seal

Style : Other, Multispring, unbalanced, independent of direction of rotation

Tolerance : 0.02 mm

Temperature : 20C to +180C

Shape : Round

Material : SS316, Carbon, Silicon Carbide, Viton

Application : Pumps, compressors, chemical and pharmaceutical industry

AWS12 Seal

Style : Other, Example Style

Tolerance : Example Tolerance

Temperature : Example Temperature

Shape : Example Shape

Material : Example Material

Application : Example Application

ARB00 Mechanical seal

Style : Spring Loaded, Other

Tolerance : Precision Grade

Temperature : Up to 120C

Shape : Circular

Material : Stainless Steel and Nitrile Rubber

Application : Pump Sealing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS