AMS20B - AMS20BT Seal

AMS20B - AMS20BT Seal Specification

- Tolerance

- 0.02 mm

- Hardness

- 705 Shore A

- Feature

- Excellent oil resistance, anti-wear

- Material

- Nitrile Rubber (NBR)

- Style

- Lip Seal

- Shape

- Round

- Temperature

- -30C to +100C

- Application

- Rotating shaft sealing, hydraulic equipment

- Compression Set

- Low

- Standard

- DIN 3760

- Thickness

- 5 mm

- Diameter

- 20 mm

- Color

- Black

- Model Number

- AMS20B / AMS20BT

- Installation

- Press fit

- Resistance Type

- Resistant to water, oil, and greases

About AMS20B - AMS20BT Seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

OPERATING LIMITS:

- d1= 14 to 100 mm

- p= 60 kg/cm²

- v= 25 m/s

- t= -15 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

The balanced contact surface design allows the me - chanical seal to be used in applications with high pressures without suffering premature wear. The set of springs placed around the contact surface of the rotating part generates a more uniformed load than in models with a single spring. It can be supplied with PTFE wedge for highly aggressive chemicals with high temperatures. Seal compliant with standard EN 12756 (KB)

Outstanding Oil and Wear Resistance

Engineered with high-quality nitrile rubber (NBR), the AMS20B - AMS20BT Seal delivers excellent oil resistance and anti-wear performance. Its robust material composition ensures reliable sealing even in challenging environments where hydraulic fluids, oils, and greases are present, maximizing your equipment lifespan.

Precision Manufacturing and Installation

Manufactured according to DIN 3760, this seal features a precise round shape and maintains a consistent tolerance of 0.02 mm. The 705 Shore A hardness strikes the ideal balance between flexibility and structural integrity. Designed for press-fit installation, setup is easy and secure for manufacturers, suppliers, and end-users alike.

FAQ's of AMS20B - AMS20BT Seal:

Q: How is the AMS20B - AMS20BT Seal installed?

A: The AMS20B - AMS20BT Seal is designed for press-fit installation. Simply align the seal with the shaft opening and press it firmly in place to achieve an effective and secure fit.Q: What applications are suitable for this seal?

A: This seal is ideal for rotating shaft sealing in hydraulic equipment, as well as other industrial machinery exposed to water, oil, and greases. Its robust construction and excellent resistance make it a preferred choice for manufacturers and suppliers.Q: When should I choose a lip seal with low compression set?

A: Opt for a lip seal with low compression set, like the AMS20B - AMS20BT, when you require consistent sealing performance over time, especially in conditions involving fluctuating pressures or high-frequency shaft movement.Q: Where can the AMS20B - AMS20BT Seal be used?

A: The AMS20B - AMS20BT Seal is suitable for use in industrial and hydraulic systems, manufacturing units, and maintenance settings throughout India, wherever reliable shaft sealing solutions are required.Q: What is the process for selecting the correct seal size?

A: Identify your shaft diameter and groove dimensions. The AMS20B - AMS20BT Seal fits a 20 mm diameter, 5 mm thickness configuration. Its tolerance of 0.02 mm ensures compatibility with standard fittings.Q: What benefits does nitrile rubber (NBR) provide in this seal?

A: Nitrile rubber makes the seal highly resistant to oils, water, and greases and offers superior anti-wear characteristics, extending service life and reducing maintenance needs for your equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

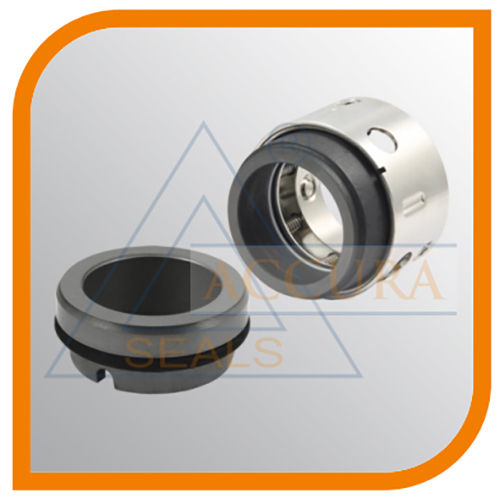

AS18B mechanical seal

Material : Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

Temperature : 20C to +180C

Style : Other, AS18B Single Spring

Application : Water pumps, chemical pumps, oil pumps, centrifugal pumps

Hardness : High hardness for superior wear resistance

Shape : Round

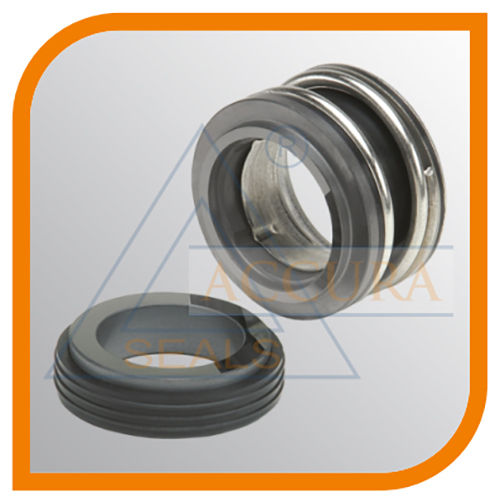

AMB84 Seal

Material : Nitrile Rubber (NBR)

Temperature : 30C to +120C

Style : Other, Hydraulic Rod Seal

Application : Hydraulic cylinders, pneumatic cylinders, valves

Hardness : 60 90 Shore A

Shape : Round

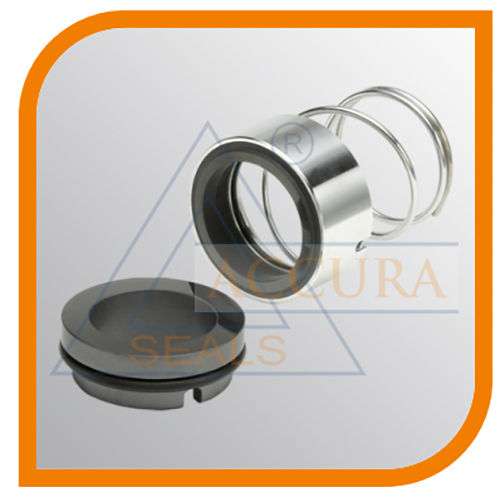

AMS15D Double seal

Material : Metal and rubber composite

Temperature : Hightemperature resistance

Style : Other, Double seal

Application : Seal for industrial pumps

Hardness : High hardness suitable for heavyduty applications

Shape : Circular

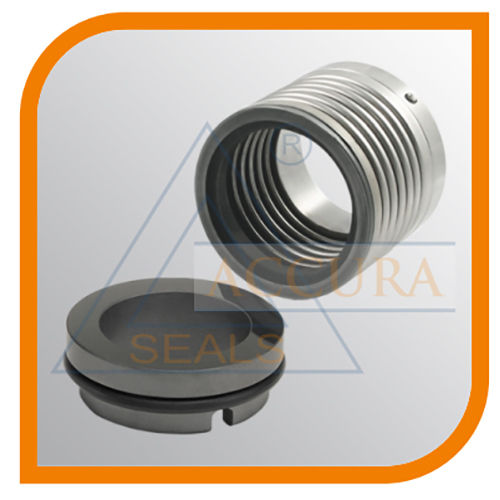

ARB02 Seal

Material : Carbon Ceramic Stainless Steel

Temperature : 20C to 200C

Style : Other, Single Spring Seal

Application : Rotating equipment sealing

Hardness : Medium

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS