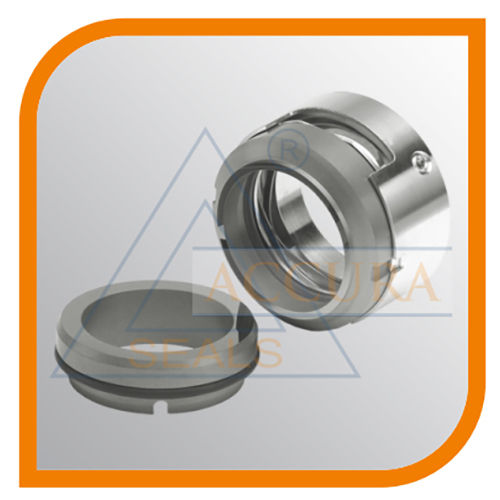

AWS10 single seal

AWS10 single seal Specification

- Hardness

- 6090 Shore A

- Tolerance

- 0.05 mm

- Material

- Carbon, Ceramic, Nitrile Rubber, Stainless Steel

- Style

- Single Spring Seal

- Shape

- Round

- Temperature

- -20C to 180C

- Application

- Pumps, Mixers, Agitators

- Shaft Diameter

- 12mm to 100mm

- Spring Type

- Single Coil

- Seal Face Combination

- Carbon vs Ceramic/Silicon Carbide/Tungsten Carbide

- Speed

- Up to 3000 RPM

- Pressure Range

- Up to 10 Bar

- Rotation

- Unidirectional/Bidirectional

- O-Ring Material

- Nitrile, EPDM, Viton

- Installation

- Easy to Install, Compact Design

About AWS10 single seal

CHARACTERISTICS:

- Unbalanced.

- Single conical spring.

- Dependent on the rotation direction

- Exchangeable Contact Surfaces.

OPERATING LIMITS -

- d1= 10 to 100 mm

- p= 10 kg/cm²

- v= 20 m/s

- t= -20 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

Available with a pumping ring on the casing to reduce the temperature between the contact surfaces and facilitate the barrier fluid movement in the case of double mounting (AWS10-F)

Reliable Sealing for Challenging Applications

AWS10 single spring seals are engineered for demanding environments. Their high-grade materials and precision build handle tough industrial applications, including pumps, mixers, and agitators. With robust sealing performance at pressures up to 10 Bar and temperatures ranging from -20C to 180C, AWS10 delivers dependable results. The carefully selected seal face combinations and O-ring materials enhance chemical resistance, making them suitable for varied fluids and conditions.

Precision Engineering for Easy Installation

Designed with a compact, round shape and tight tolerance (0.05 mm), AWS10 seals are user-friendly and fit seamlessly into constrained spaces. The single coil spring style ensures consistent sealing force and simplified maintenance. Installation requires minimal effort, reducing downtime and operational costs. AWS10s well-matched components provide a superior seal on shafts ranging from 12mm up to 100mm, making them a go-to solution for system integrators and maintenance teams.

FAQs of AWS10 single seal:

Q: How is the AWS10 single seal installed in pumps and mixers?

A: The AWS10 single seal features a compact, round design with a single coil spring, making it straightforward to install on shafts measuring 12mm to 100mm. Its easy-fit construction and user-friendly assembly ensure quick installation with minimal requirements, reducing equipment downtime.Q: What materials are used in the construction of the AWS10 seal facing and O-rings?

A: The AWS10 employs seal faces in Carbon versus Ceramic, Silicon Carbide, or Tungsten Carbide to suit various applications. O-rings are available in Nitrile, EPDM, or Viton, providing compatibility with a wide range of operating fluids and temperature conditions.Q: When should I choose the AWS10 seal for my equipment?

A: The AWS10 is ideal when reliability under moderate pressure (up to 10 Bar), varied shaft sizes (12mm100mm), and operation at speeds up to 3000 RPM are required. It is especially suitable for pumps, agitators, and mixers in the chemical, water treatment, and process industries.Q: Where is the AWS10 seal commonly used?

A: This seal is widely utilized in pump systems, mixers, and industrial agitators, especially where compactness and reliability are essential. It is designed for versatility in various sectors and is suitable for equipment operating under challenging temperature and pressure ranges in India.Q: What is the benefit of using a single coil spring in this seal type?

A: A single coil spring delivers uniform sealing force, enhances durability, and simplifies the overall maintenance process. This design ensures reliable sealing performance across the specified shaft diameter and speed range.Q: How does the AWS10 seal handle temperature variations?

A: The AWS10 is engineered to withstand temperatures from -20C to 180C, aided by the selection of appropriate O-ring materials (Nitrile, EPDM, or Viton). This allows for stable sealing performance in both extreme cold and heat, making it suitable for diverse applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

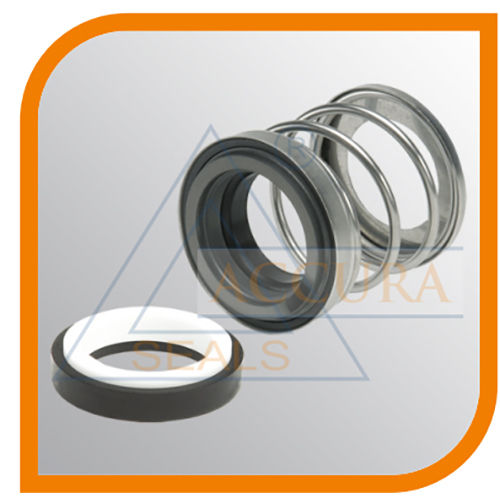

PNL Mechanical seal

Hardness : 6070 Shore A

Temperature : 20C to 180C

Material : Carbon, Ceramic, Stainless Steel, Nitrile Rubber

Tolerance : 0.05 mm

Shape : Round

Application : Pumps, Compressors, Mixers, Blowers

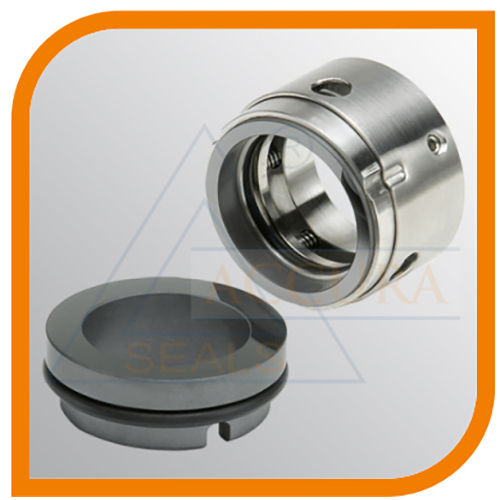

ATB16 mechanical seal

Hardness : High

Temperature : Up to 200C

Material : Ceramic and stainless steel

Tolerance : 0.01 mm

Shape : Circular

Application : Pumps and rotary equipment

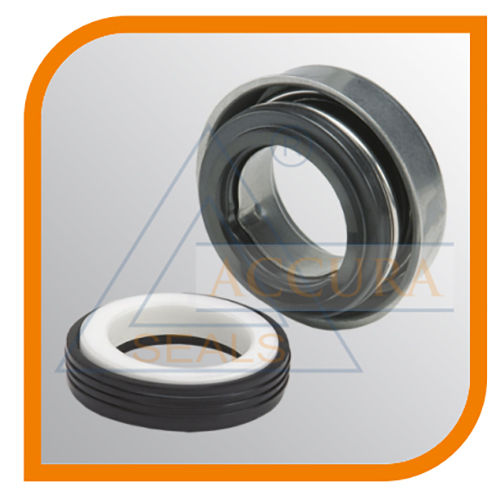

ARB03 - ARB03A - ARB03B Mechanical seal

Hardness : High

Temperature : Up to 120C

Material : Carbon Ceramic NBR

Tolerance : 0.02 mm

Shape : Round

Application : Pump

AMS11 Seal compliant

Hardness : Medium

Temperature : 0C to 250C

Material : Stainless Steel

Tolerance : 0.05 mm

Shape : Round

Application : Sealing for rotating equipment

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS