AMS10D Double seal

AMS10D Double seal Specification

- Feature

- High wear resistance, Excellent sealing performance

- Hardness

- 70 Shore A

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR)

- Style

- Double Seal

- Shape

- Round

- Temperature

- -20C to +100C

- Application

- Hydraulic Cylinders, Pneumatic Systems

- Color

- Black

- Pressure Rating

- Up to 10 bar

- Packing Type

- Individual Polybag

- Diameter Range

- 10 mm to 120 mm

About AMS10D Double seal

Double seal for working with barrier fluids in which the springs are isolated from the fluid product. API 53A and AP I54 assemblies. Recommended in applications with toxic, pollutant, or potentially dangerous products in which safety is an important factor. Available with a pumping ring on the casing to reduce the temperature between the contact surfaces and facilitate the barrier fluid movement (AMS10-F).Available in a balanced version with a stepped shaft ( AM10DB). Contact surface kits are available.

- Unbalanced.

- System attached to the shaft by Allen screws.

- Not dependent on the rotation direction.

- d1 = 18 to 100 mm

- p= 16 kg/cm²

- v = 20 m/s

- t = -15 to 200 °C (*)

Exceptional Sealing Performance

AMS10D Double Seal excels in providing reliable sealing solutions for demanding hydraulic and pneumatic applications. Its double seal design minimizes fluid leakage and enhances system integrity even under high pressure conditions, contributing to extended equipment lifespan.

High Durability and Versatility

Engineered from Nitrile Rubber (NBR), the AMS10D demonstrates high wear resistance and flexibility in diverse environments. Suitable for diameters ranging from 10 mm to 120 mm, this seal withstands varying temperatures and retains its effectiveness in a range of operational contexts.

FAQ's of AMS10D Double seal:

Q: How is the AMS10D Double Seal installed in hydraulic cylinders and pneumatic systems?

A: The AMS10D Double Seal is typically fitted in cylinder grooves, ensuring a precise seal. Installation should follow manufacturer guidelines to prevent damage to the seal or system and guarantee optimal performance.Q: What temperature and pressure ranges can the AMS10D Double Seal withstand?

A: This seal operates effectively in temperatures from -20C to +100C and can handle pressures up to 10 bar, making it suitable for a variety of industrial settings.Q: When should the AMS10D Double Seal be replaced?

A: Replacement is recommended when signs of wear, deformation, or leakage occur during routine maintenance. Timely replacement helps maintain system efficiency and prevents equipment failure.Q: Where can AMS10D Double Seals be sourced in India?

A: AMS10D Double Seals can be purchased from authorized manufacturers, suppliers, and retailers across India, ensuring quality and authenticity.Q: What process is used to pack the AMS10D Double Seal?

A: Each seal is individually packed in a polybag, safeguarding it from contamination, damage, and environmental exposure during transit and storage.Q: How should the AMS10D Double Seal be used for optimal performance?

A: To achieve the best sealing results, the AMS10D Double Seal should be applied within its specified diameter, tolerance, temperature, and pressure ratings. Adhering to installation procedures maximizes longevity and effectiveness.Q: What are the benefits of using a double seal design in hydraulic and pneumatic systems?

A: The double seal style provides enhanced leakage prevention, greater operational reliability, and superior wear resistance, reducing maintenance and increasing the service life of equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

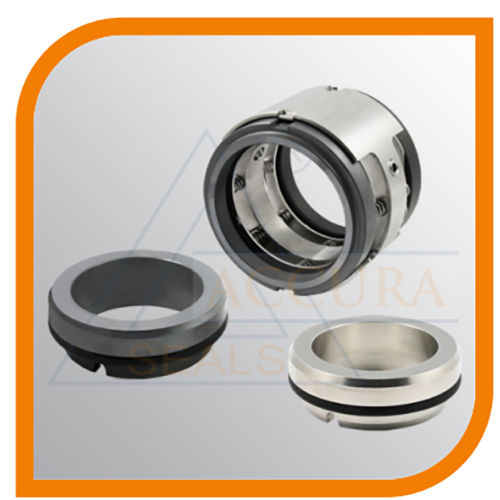

AS18B mechanical seal

Tolerance : 0.01 mm

Application : Water pumps, chemical pumps, oil pumps, centrifugal pumps

Temperature : 20C to +180C

Style : Other, AS18B Single Spring

Material : Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

Shape : Round

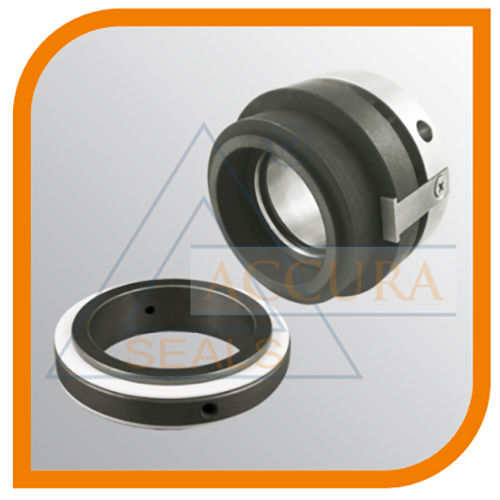

AMS28 Seal

Tolerance : 0.05 mm

Application : Hydraulic Cylinders

Temperature : 30C to +110C

Style : Other, Hydraulic Rod Seal

Material : Nitrile Rubber (NBR)

Shape : Round

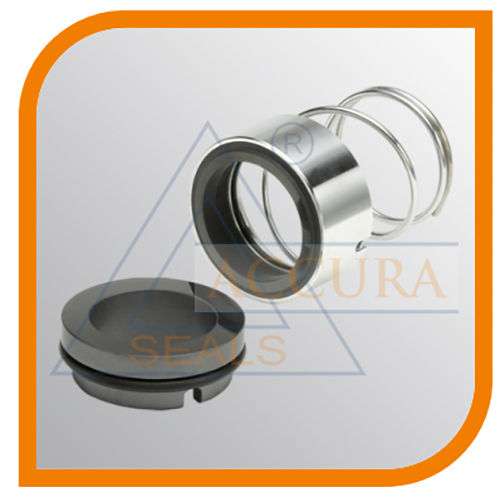

AMS27 multi-spring mechanical seal

Tolerance : 0.02 mm

Application : Pumps, compressors, chemical and pharmaceutical industry

Temperature : 20C to +180C

Style : Other, Multispring, unbalanced, independent of direction of rotation

Material : SS316, Carbon, Silicon Carbide, Viton

Shape : Round

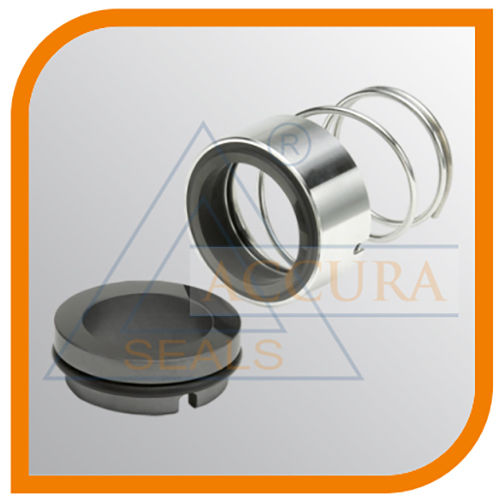

AS18 -AS19 Single mechanical seal

Tolerance : High tolerance for industrial applications

Application : Pumps Agitators

Temperature : Up to 200C

Style : Other, Single Mechanical Seal

Material : Stainless Steel Carbon

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS