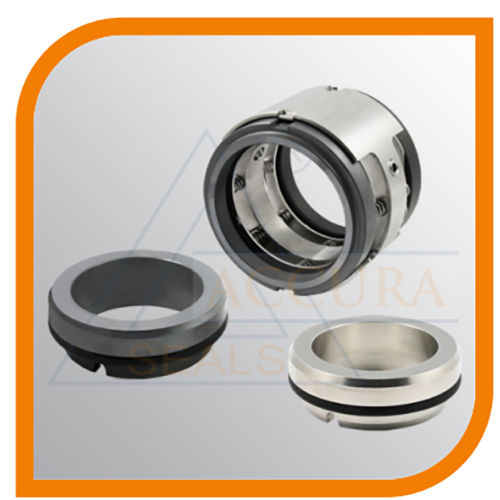

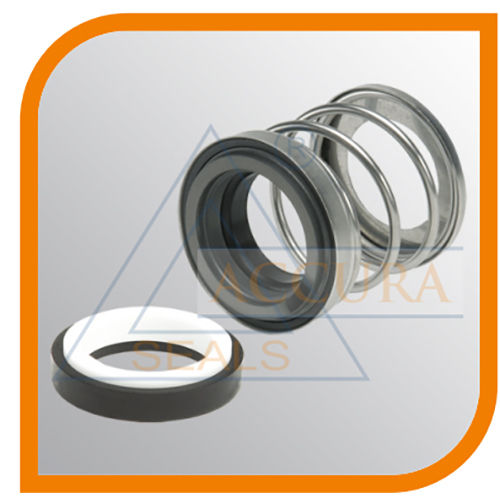

AMS20 - AMS20T Seal

AMS20 - AMS20T Seal Specification

- Hardness

- 60 90 Shore A

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR), Fluoroelastomer (FKM)

- Style

- Mechanical Seal

- Shape

- Round

- Temperature

- -20C to +200C

- Application

- Rotary Shaft Sealing in Pumps, Motors, Compressors

- Size Range

- Custom and standard sizes available

- Pressure Resistance

- Up to 10 BAR

- Color

- Black, Brown, Red

- Standards

- DIN 3760 / ISO 6194

- Durometer Range

- 70, 80, 90 Shore A

- Media Compatibility

- Mineral oils, Synthetic lubricants, Water, Gases

- Installation Type

- Static and dynamic sealing

About AMS20 - AMS20T Seal

CHARACTERISTICS:

- Unbalanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

OPERATING LIMITS -

- d1= 14 to 100 mm

- p= 10 kg/cm²

- v= 20 m/s

- t= -15 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

The set of springs placed around the contact surface of the rotating part generates a more uniformed load than in models with a single spring. The AMS20 is suitable for many different applications. Seal compliant with standard EN 12756 (KU). The AMS20T uses a PTFE wedge as a secondary seal and is appropriate for highly aggressive chemicals and for thermal oils with high temperatures. The version in inches has a standard stationary PF. L22 part.

Versatile Media Compatibility

The AMS20 - AMS20T Seal can handle a variety of fluids, including mineral oils, synthetic lubricants, water, and gases. Its robust material choices, NBR and FKM, ensure reliable performance across a range of operating conditions and applications. As a result, its highly suitable for use in pumps, motors, and compressors where different fluids may be present.

Engineered for Precision and Strength

Built according to DIN 3760 and ISO 6194 standards, the AMS20 AMS20T Seal offers a tolerance of 0.05 mm and pressure resistance up to 10 BAR. The round shape and mechanical seal style are designed to ensure effective sealing performance in static and dynamic conditions alike, supporting durable operation and reduced maintenance needs.

Adaptable Sizing and Hardness Options

Customers can select from custom or standard sizes, with durometer options ranging between 60 and 90 Shore A. This adaptability allows the AMS20 - AMS20T Seal to fit specific application requirements, offering optimized sealing solutions for various installation needs throughout India.

FAQs of AMS20 - AMS20T Seal:

Q: How do I determine the correct size and hardness of the AMS20 - AMS20T Seal for my application?

A: Choosing the right size and hardness depends on your equipments specifications and operating environment. Custom and standard sizes are available, while durometer values range from 60 to 90 Shore A. Consult your equipment manual or speak with our technical team to select the optimum seal for your sealing needs.Q: What types of media can the AMS20 - AMS20T Seal handle?

A: This seal is compatible with mineral oils, synthetic lubricants, water, and gases, thanks to its high-quality NBR and FKM construction. Its materials withstand a broad spectrum of fluids commonly found in pumps and compressors.Q: When should the AMS20 - AMS20T Seal be replaced in rotary shaft equipment?

A: Seal replacement is necessary if you detect leaks, excessive wear, or diminished performance in your pumps or motors. Regular inspections according to your maintenance schedule will help ensure timely replacement and continued equipment efficiency.Q: Where can I install the AMS20 - AMS20T Seal?

A: The AMS20 - AMS20T Seal is suitable for rotary shaft sealing in pumps, motors, compressors, and related machinery. It can be used for both static and dynamic sealing, offering versatility across various industrial setups.Q: What is the installation process for the AMS20 - AMS20T Seal?

A: Properly clean the shaft and housing, apply lubrication if necessary, and press the seal evenly into place. Detailed instructions and support are available to ensure correct installation and optimal sealing.Q: What benefits does the AMS20 - AMS20T Seal provide over standard seals?

A: The AMS20 - AMS20T Seal delivers higher pressure resistance (up to 10 BAR), a broad temperature range (-20C to +200C), and compliance with international standards. Its precise tolerance and media compatibility lead to longer service life and reduced downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS10D Double seal

Application : Hydraulic Cylinders, Pneumatic Systems

Temperature : 20C to +100C

Hardness : 70 Shore A

Tolerance : 0.05 mm

Shape : Round

Style : Other, Double Seal

ARB50 balanced seal

Application : Pumps, Mixers, Compressors

Temperature : 20C to +200C

Hardness : 6080 Shore A

Tolerance : 0.05 mm

Shape : Round

Style : Mechanical Seal

AMB86 Seal

Application : Automotive and Industrial Equipment

Temperature : 20C to +100C

Hardness : 70 Shore A

Tolerance : 0.1 mm

Shape : Round

Style : Other, Rotary Shaft Seal

PNL Mechanical seal

Application : Pumps, Compressors, Mixers, Blowers

Temperature : 20C to 180C

Hardness : 6070 Shore A

Tolerance : 0.05 mm

Shape : Round

Style : Other, Single Spring, Balanced Type

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS