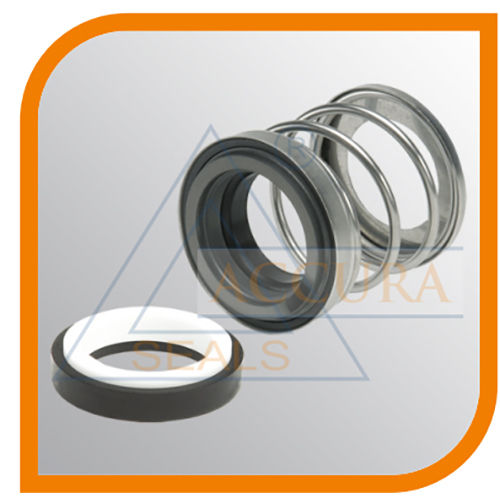

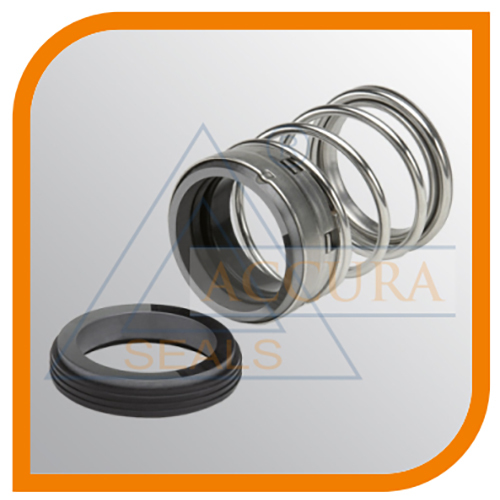

PNL Mechanical seal

PNL Mechanical seal Specification

- Hardness

- 60-70 Shore A

- Tolerance

- 0.05 mm

- Material

- Carbon, Ceramic, Stainless Steel, Nitrile Rubber

- Style

- Single Spring, Balanced Type

- Shape

- Round

- Temperature

- -20C to 180C

- Application

- Pumps, Compressors, Mixers, Blowers

- Secondary Seal

- NBR, EPDM, Viton

- Rotary Face Material

- Carbon, Ceramic

- Standard

- DIN 24960, ISO 3069

- Pressure Rating

- Up to 10 bar

- Color

- Silver/Black

- Packing Type

- Box

- Stationary Face Material

- Ceramic, Silicon Carbide

- Speed Limit

- Up to 3000 rpm

- Corrosion Resistance

- Yes

- Shaft Diameter

- 12 mm to 100 mm

About PNL Mechanical seal

CHARACTERISTICS:

- Unbalanced.

- Single Cylindrical Spring

- Not dependent on the rotation direction.

OPERATING LIMITS -

- d1=8 to 40 mm

- p= 12kg/cm²

- v= 10 m/s

- t= -20 to + 120ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

Mechanical seal with a simple design for general use.

Engineered for Versatility and Durability

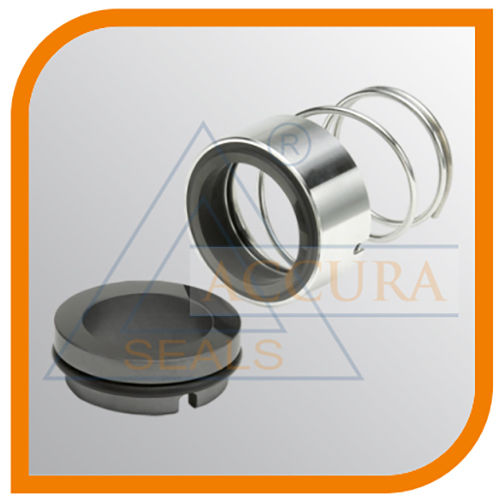

Our PNL Mechanical Seal stands out for its adaptability, compatible with shaft sizes from 12 mm up to 100 mm. Constructed with corrosion-resistant materials, including carbon, ceramic, stainless steel, and nitrile rubber, it ensures reliable sealing in harsh industrial environments. The balanced, single-spring design improves longevity, supporting continuous operation at speeds up to 3000 rpm.

Compliant with Global Standards

Certified according to DIN 24960 and ISO 3069, the PNL Mechanical Seal meets international quality and performance benchmarks. Its strict tolerance of 0.05 mm guarantees precise fitment, which is essential for efficient operation in pumps, compressors, mixers, and blowers. The robust packing (box type) adds protection during storage and transportation.

FAQs of PNL Mechanical seal:

Q: How does the PNL Mechanical Seal provide optimal sealing under high pressure?

A: The PNL Mechanical Seal is designed with precision materials such as carbon and ceramic faces, along with a balanced single spring mechanism. These features ensure dependable sealing performance even at pressures up to 10 bar, making it suitable for critical industrial operations.Q: What are the recommended applications for this mechanical seal?

A: This seal is ideal for pumps, compressors, mixers, and blowers across industrial sectors. Its versatility in handling shaft diameters from 12 mm to 100 mm and its robust material construction make it suitable for a broad range of fluid management and process applications.Q: When should I consider using secondary seals like NBR, EPDM, or Viton?

A: The choice of secondary seal depends on the process fluid, operating temperature, and chemical compatibility. NBR is best for oils and fuels, EPDM suits water and steam, while Viton is preferred for aggressive chemicals and high-temperature applications. Use the most appropriate one for your specific process environment.Q: Where can the PNL Mechanical Seal be installed?

A: The seal is widely used in both industrial and commercial settings, including manufacturing plants, water treatment facilities, refineries, and processing industries. It can be easily integrated into existing equipment that adheres to DIN 24960 or ISO 3069 standards.Q: What is the installation process for this mechanical seal?

A: Installation involves placing the seal onto a cleaned, compatible shaft and ensuring it aligns with equipment specifications. The single spring and balanced design make assembly straightforward, maintaining a tight fit with minimal adjustment. Professional installation is recommended to maximize performance and longevity.Q: How does corrosion resistance benefit the user?

A: The corrosion-resistant materials used in the construction of this seal protect against chemical attack and wear, significantly extending service life and minimizing maintenance costs. This leads to reduced downtime and enhanced reliability of equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AFH - AFHC Seal

Shape : Round

Style : Other, AFHAFHC

Application : Hydraulic and pneumatic systems

Temperature : 30C to +100C

Material : NBR (Nitrile Rubber)

Hardness : 705 Shore A

ARB00U and ARB00L Mechanical seal

Shape : Circular

Style : Other, Spring Loaded

Application : Pump sealing applications

Temperature : Up to 200C

Material : Stainless Steel and Carbon

Hardness : High hardness

AMS20 - AMS20T Seal

Shape : Round

Style : Mechanical Seal

Application : Rotary Shaft Sealing in Pumps, Motors, Compressors

Temperature : 20C to +200C

Material : Nitrile Rubber (NBR), Fluoroelastomer (FKM)

Hardness : 60 90 Shore A

AS18 -AS19 Single mechanical seal

Shape : Round

Style : Other, Single Mechanical Seal

Application : Pumps Agitators

Temperature : Up to 200C

Material : Stainless Steel Carbon

Hardness : High hardness

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS