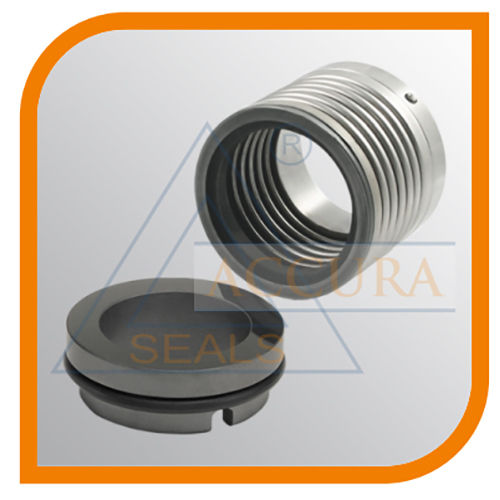

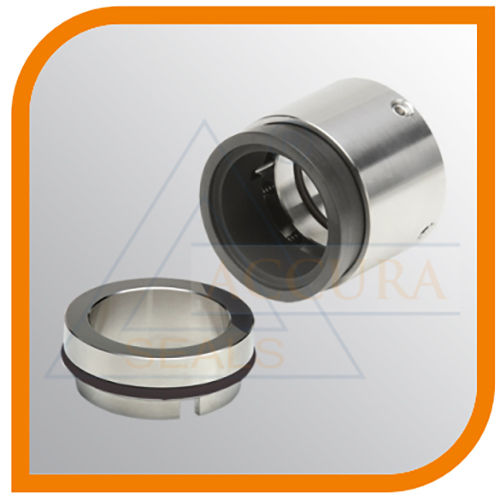

ARB01-ARB01S-ARB04-ARB04A and ARB06 Mechanical seal

ARB01-ARB01S-ARB04-ARB04A and ARB06 Mechanical seal Specification

- Hardness

- 60-80 (Shore A)

- Tolerance

- 0.01 mm

- Material

- Carbon, Ceramic, Silicon Carbide, Tungsten Carbide, Nitrile Rubber, Viton, EPDM

- Style

- Unbalanced, Single Spring, Rubber Bellow Type

- Shape

- Round

- Temperature

- -20C to +120C

- Application

- Pumps, Mixers and Agitators

- Face Combination

- Carbon vs Ceramic, SiC vs SiC, TC vs TC

- Speed Capability

- Up to 4000 rpm

- Seal Type

- Rotary, Stationary

- Shaft Diameter

- 12 mm to 100 mm

- Compliance

- DIN 24960, ISO 3069

- Installation

- Easy to install, replaceable design

- Pressure Range

- Up to 20 bar

- Spring Type

- Single/Multiple Springs

- O-ring Type

- NBR, EPDM, Viton

- Media Compatibility

- Water, Oil, Chemicals, Mild Acids

About ARB01-ARB01S-ARB04-ARB04A and ARB06 Mechanical seal

CHARACTERISTICS:

- Unbalanced.

- Not dependent on the rotation direction

- Single cylindrical spring.

OPERATING LIMITS -

- d1= 9.52 to 101.60mm

- p= 10 kg/cm²

- v= 10 m/s

- t= -15 to +200ºC (*)

- Mechanical seal with a simple design for general use.

- Type ARB04/ ARB04A are standardised models in accordance with EN 12756 (KU).

Reliable Sealing Performance

ARB01-ARB06 mechanical seals provide unmatched reliability for critical rotating equipment like pumps, mixers, and agitators. Their robust construction, compliance with international standards (DIN 24960, ISO 3069), and compatibility with harsh media make them ideal for demanding industrial settings. With high pressure and speed tolerances, these seals ensure minimal leakage and long service life.

Versatile Material and Media Compatibility

Crafted from high-grade materials such as carbon, ceramic, silicon carbide, tungsten carbide, and resilient elastomers like NBR, EPDM, and Viton, these seals perform flawlessly with water, oils, chemicals, and mild acids. Their chemical resistance and durability protect equipment and process integrity across diverse applications in manufacturing, processing, and utility sectors.

Ease of Installation and Maintenance

The design emphasizes simple, tool-friendly installation and user-friendly maintenance. Single or multiple spring mechanisms, together with a replaceable architecture, reduce downtime significantly. Each seal upholds tight tolerances for consistent fitting, with easily accessible O-ring options suiting a variety of operational temperatures and pressures.

FAQs of ARB01-ARB01S-ARB04-ARB04A and ARB06 Mechanical seal:

Q: How are the ARB01-ARB06 mechanical seals installed and replaced?

A: These seals are engineered for quick and straightforward installation using commonly available tools. The replaceable, modular design means that maintenance personnel can remove and fit new seals without specialized training, minimizing equipment downtime.Q: What types of media are these mechanical seals compatible with?

A: ARB01-ARB06 seals are suitable for water, oils, chemicals, and mild acids. Their robust construction and use of resistant materials (such as NBR, EPDM, and Viton for O-rings) enable seamless operation in a variety of industrial and processing environments.Q: When should I choose a specific face combination (Carbon vs Ceramic, SiC vs SiC, TC vs TC)?

A: The choice depends on the application: Carbon vs Ceramic is ideal for water and mild chemicals, SiC vs SiC for abrasive or challenging fluids, and TC vs TC for aggressive, high-pressure, or high-speed environments. Selecting the optimal face combination ensures longevity and leak-free performance.Q: Where can ARB01-ARB06 mechanical seals be used?

A: These seals are applicable in pumps, mixers, and agitators found in water treatment plants, chemical processing units, manufacturing facilities, as well as oil and utility sectors across India. Their wide temperature and pressure tolerances suit demanding industrial use-cases.Q: What makes these seals easy to maintain?

A: The seals design incorporates replaceable wear parts, accessible O-rings, and single/multiple spring mechanisms, making regular inspection, cleaning, and component replacement efficient. This reduces maintenance complexity and extends service intervals.Q: How does compliance with DIN 24960 and ISO 3069 benefit end users?

A: Compliance with these global standards ensures dimensional interchangeability, reliability, and consistent performance. This makes it easier for users to source, install, and replace seals across different brands and equipment, reducing costs and operational challenges.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMB84 Seal

Application : Hydraulic cylinders, pneumatic cylinders, valves

Material : Nitrile Rubber (NBR)

Tolerance : 0.05 mm

Hardness : 60 90 Shore A

Style : Other, Hydraulic Rod Seal

Temperature : 30C to +120C

AMS14 Seal

Application : Hydraulic and pneumatic sealing

Material : Nitrile Rubber (NBR)

Tolerance : 0.1 mm

Hardness : 6090 Shore A

Style : Other, AMS14

Temperature : 30C to +120C

AWS12 Seal

Application : Example Application

Material : Example Material

Tolerance : Example Tolerance

Hardness : Example Hardness

Style : Other, Example Style

Temperature : Example Temperature

AS40A Single mechanical seal

Application : Water pumps, Submersible pumps, Industrial pumps

Material : Carbon, Ceramic, Nitrile Rubber, Stainless Steel

Tolerance : 0.02 mm

Hardness : 6070 HRC

Style : Other, Single Mechanical Seal

Temperature : 30C to 200C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS