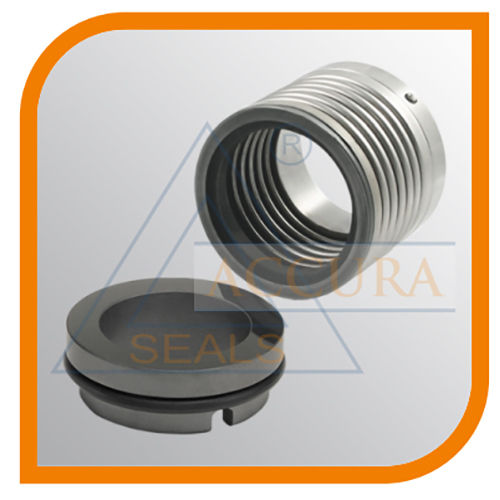

AWS30 - AWS30A Seal

AWS30 - AWS30A Seal Specification

- Tolerance

- 0.05 mm

- Feature

- Excellent Sealing Performance

- Hardness

- 80 5 Shore A

- Material

- Nitrile Rubber (NBR)

- Style

- AWS30 / AWS30A

- Shape

- Round

- Temperature

- -30C to +100C

- Application

- Hydraulic Cylinders

- Compression Set

- Low

- Surface Finish

- Smooth

- Color

- Black

- Installation Type

- Internal/External

- Pressure Resistance

- Up to 250 Bar

- Durometer Range

- 70-90 Shore A

- Chemical Resistance

- Good Resistance to Oils and Fuels

About AWS30 - AWS30A Seal

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction

- d1= 18 to 100 mm

- p= 35 kg/cm²

- v= 20 m/s

- t= -15 to+200ºC (*)

The wave spring is protected from the fluid. Ideal for using in cleaning processes since the possibility of particles adhering to the seal is considerably reduced. Internally balanced, with no need for a stepped shaft (AWS10B). Suitable for working in applications with high pressures. The O-ring resting on the shaft does not cause wear as there is no axial movement (changes in pressure). Seal compliant with standard EN 12756 (KU). Standard L16 type stationary part (AWS30)

Superior Hydraulic Sealing Solution

The AWS30 / AWS30A Seal delivers optimal sealing for hydraulic cylinders, making it ideal for high-pressure applications. Its advanced NBR compound provides outstanding resistance to oils and fuels, ensuring durable and reliable operation in industrial conditions. As an internal and external seal, it stands out for versatility and robust compression properties.

Precision and Reliability in Every Application

With a tolerance of 0.05 mm and a hardness rating of 80 5 Shore A, the AWS30 / AWS30A Seal guarantees precision fit and stability. Its smooth surface finish minimizes friction, while the low compression set maintains sealing integrity over time, reducing the need for frequent replacement.

FAQ's of AWS30 - AWS30A Seal:

Q: How is the AWS30 / AWS30A Seal installed in hydraulic cylinders?

A: The AWS30 / AWS30A Seal is designed for both internal and external installation. It fits securely into the grooves of hydraulic cylinders, providing a leak-proof barrier against high-pressure fluids. Installation typically requires standard sealing tools and can be carried out by trained maintenance personnel.Q: What materials and features make the AWS30 / AWS30A Seal ideal for hydraulic applications?

A: Crafted from Nitrile Rubber (NBR), the AWS30 / AWS30A Seal features excellent resistance to oils and fuels, low compression set, and a durometer hardness of 80 5 Shore A. Its smooth surface finish and precise tolerance ensure reliable sealing and longevity in hydraulic systems.Q: When should I consider using the AWS30 / AWS30A Seal?

A: This seal should be used when high pressure resistance (up to 250 Bar), robust chemical compatibility, and stable sealing performance are required. It is particularly suited for demanding hydraulic cylinder applications operating between -30C to +100C.Q: Where is the AWS30 / AWS30A Seal sourced or supplied in India?

A: The AWS30 / AWS30A Seal is available through authorized manufacturers, retailers, and suppliers in India who specialize in hydraulic sealing solutions. They offer a range of sizes and support for various custom requirements.Q: What is the benefit of choosing a seal with low compression set and tight tolerance?

A: Low compression set ensures the seal maintains its shape and sealing ability over prolonged use, minimizing leakage and downtime. Tight dimensional tolerance (0.05 mm) guarantees precise fitting, enhancing reliability and reducing installation errors.Q: How does the chemical resistance of the AWS30 / AWS30A Seal contribute to its durability?

A: The nitrile rubber compound provides good resistance to oils and fuels commonly found in hydraulic systems. This property protects the seal from degradation, prolongs service life, and maintains consistent performance under various operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AS60DIN single seal

Tolerance : 0.02 mm

Shape : Round/ORing

Hardness : 85 Shore A

Temperature : 30C to +120C

Application : DIN Standard Fittings, Hygienic and Sanitary Processing

Style : Other, Single Seal

AMB84 Seal

Tolerance : 0.05 mm

Shape : Round

Hardness : 60 90 Shore A

Temperature : 30C to +120C

Application : Hydraulic cylinders, pneumatic cylinders, valves

Style : Other, Hydraulic Rod Seal

AS40A Single mechanical seal

Tolerance : 0.02 mm

Shape : Round

Hardness : 6070 HRC

Temperature : 30C to 200C

Application : Water pumps, Submersible pumps, Industrial pumps

Style : Other, Single Mechanical Seal

AWS12 Seal

Tolerance : Example Tolerance

Shape : Example Shape

Hardness : Example Hardness

Temperature : Example Temperature

Application : Example Application

Style : Other, Example Style

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS