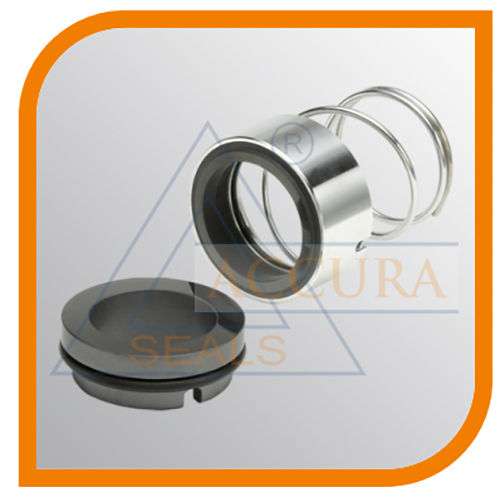

AS40A Single mechanical seal

AS40A Single mechanical seal Specification

- Tolerance

- 0.02 mm

- Hardness

- 60-70 HRC

- Material

- Carbon, Ceramic, Nitrile Rubber, Stainless Steel

- Style

- Single Mechanical Seal

- Shape

- Round

- Temperature

- -30C to 200C

- Application

- Water pumps, Submersible pumps, Industrial pumps

- Stationary Face

- Ceramic/Silicon Carbide

- Installation

- Easy to install, ready to fit design

- Rotary Face

- Carbon/Silicon Carbide/Tungsten Carbide

- Spring Type

- Single spring

- Shaft Size

- 20 mm to 60 mm

- Metal Parts

- Stainless Steel 316/304

- Maximum Pressure

- Up to 10 bar

- Direction of Rotation

- Unbalanced, Independent of direction of rotation

- Elastomers

- Viton/NBR/EPDM/PTFE available

About AS40A Single mechanical seal

CHARACTERISTICS:

- Unbalanced.

- System attached to the shaft by allen screws.

- Dependent on the rotation direction.

- Single cylindrical spring

- d1= 20 to 100 mm

- p= 12 kg/cm²

- v= 15 m/s

- t= -20 to +200ºC (*)

Its structure allows secondary seals made of different materials to be used: FKM, Aflas, FFKM, FEP, NBR, HNBR and materials complying with special standards such as FDA, USP, EC, etc

High-Performance Sealing for Demanding Applications

The AS40A Single Mechanical Seal is designed to suit a wide range of pump operations including those in water, submersible, and industrial settings. Its compatibility with various materials and strict manufacturing tolerances ensures both resilience and long-lasting use.

Versatile Material Choices and Reliable Construction

Choose from different rotary and stationary face materials such as Carbon, Silicon Carbide, Tungsten Carbide, and Ceramic to match your specific application needs. The stainless steel hardware and diverse elastomer options provide further resistance to corrosion and harsh chemicals.

Effortless Installation and Adaptability

Benefit from a seal that is straightforward to install and ready to use, with a round shape and single spring design. Its construction is independent of shaft rotation direction, giving you flexibility no matter your pump configuration.

FAQs of AS40A Single mechanical seal:

Q: How do I install the AS40A Single Mechanical Seal in my pump?

A: The AS40A is engineered for an easy, ready-to-fit installation process. Simply follow the manufacturers instructions for aligning and securing the seal on shafts sized between 20 mm and 60 mm, regardless of the pumps rotation direction, thanks to its unbalanced and independent design.Q: What types of pumps are compatible with the AS40A Single Mechanical Seal?

A: This seal is versatile and suitable for water pumps, submersible pumps, and a variety of industrial pumps, making it a practical choice for numerous applications across different sectors.Q: When should the AS40A Single Mechanical Seal be used instead of a double seal?

A: Opt for the AS40A single seal when operating within the maximum pressure limit of 10 bar and when the fluid and environmental conditions are compatible with the material options available. Its ideal for straightforward sealing solutions that do not require double-seal protection.Q: Where is the AS40A seal manufactured, and can it be sourced in India?

A: The AS40A Single Mechanical Seal is manufactured in India and readily available through local manufacturers, suppliers, and retailers, ensuring convenient access and support for domestic customers.Q: What are the benefits of choosing materials like Silicon Carbide or Tungsten Carbide for the rotary face?

A: Selecting Silicon Carbide or Tungsten Carbide provides enhanced wear resistance, durability, and chemical compatibility, which is especially beneficial in harsh or abrasive operating environments.Q: How does the tolerance and hardness specification affect seal performance?

A: With a precise tolerance of 0.02 mm and a hardness rating of 60-70 HRC, the seal ensures minimal leakage, stable operation under pressure, and extended service life even in rigorous applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AS18B mechanical seal

Temperature : 20C to +180C

Application : Water pumps, chemical pumps, oil pumps, centrifugal pumps

Shape : Round

Hardness : High hardness for superior wear resistance

Material : Carbon, Ceramic, Stainless Steel, Viton/EPDM Elastomers

Tolerance : 0.01 mm

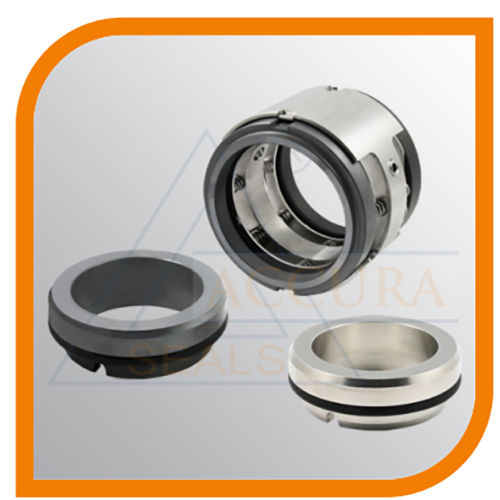

AMS10D Double seal

Temperature : 20C to +100C

Application : Hydraulic Cylinders, Pneumatic Systems

Shape : Round

Hardness : 70 Shore A

Material : Nitrile Rubber (NBR)

Tolerance : 0.05 mm

AS60DIN single seal

Temperature : 30C to +120C

Application : DIN Standard Fittings, Hygienic and Sanitary Processing

Shape : Round/ORing

Hardness : 85 Shore A

Material : EPDM/Ethylene Propylene Diene Monomer

Tolerance : 0.02 mm

AMS15D Double seal

Temperature : Hightemperature resistance

Application : Seal for industrial pumps

Shape : Circular

Hardness : High hardness suitable for heavyduty applications

Material : Metal and rubber composite

Tolerance : Precise fit and high tolerance

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS