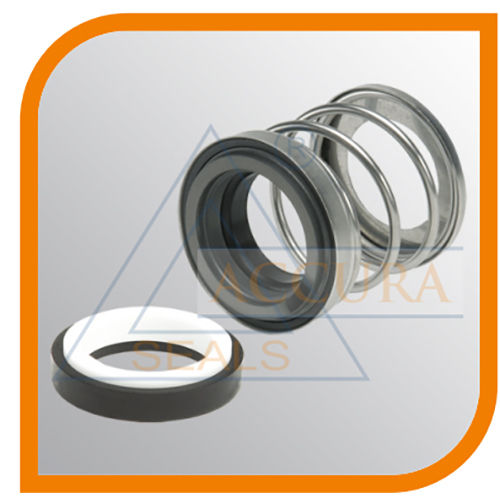

AMS29 Seal

AMS29 Seal Specification

- Hardness

- 85 Shore A

- Feature

- High Wear Resistance, Low Compression Set

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR)

- Style

- Hydraulic Rod Seal

- Shape

- Round/O-Ring

- Temperature

- -30C to +120C

- Application

- Hydraulic and Pneumatic Cylinders

- Diameter

- 29 mm

- Color

- Black

- Elongation at Break

- 300%

- Manufacturing Standard

- DIN 3771

- Pressure Rating

- Up to 400 Bar

- Media Compatibility

- Hydraulic Oils, Water Glycol, Mineral Oils

- Installation Type

- Press Fit

- Tensile Strength

- 15 MPa

About AMS29 Seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

OPERATING LIMITS

- d1 = 18 to 100 mm

- p= 25 kg/cm²

- v= 20 m/s

- t= -15 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

The fact that the springs are not in contact with the fluid makes this mechanical seal perfect for working with particle-laden fluids, as it prevents them from becoming blocked or obstructed. Its structure and design makes it ideal for vacuum operations without having to use a retaining ring. It can be used with a single, tandem-mounted (API52) or back-to back (API53) mounting system. The Oring resting on the shaft is not affected by any axial movement (changes in pressure) and therefore produces no wear on the surface of the shaft. Seal compliant with standard EN 12756 (KU).

Engineered for Longevity

Constructed from high-quality nitrile rubber, the AMS29 Seal offers excellent durability and resistance to abrasion and chemical exposure. Its advanced design ensures long-term performance even in challenging hydraulic and pneumatic systems, preventing leaks and maintaining consistent system integrity.

Strict Adherence to Standards

Manufactured according to DIN 3771 specifications, the AMS29 Seal guarantees precision and reliability. The 0.05 mm tolerance and press-fit installation provide a secure and accurate fit, reducing installation errors and maximizing sealing efficiency in high-pressure applications.

FAQ's of AMS29 Seal:

Q: How is the AMS29 Seal installed in hydraulic and pneumatic cylinders?

A: The AMS29 Seal features a press-fit installation, meaning it is manually pressed into the designated groove of the cylinder rod. Its precise tolerance of 0.05 mm ensures a snug fit, facilitating quick and secure placement without specialized tools.Q: What media is the AMS29 Seal compatible with during operation?

A: AMS29 Seal is designed for use with hydraulic oils, water glycol, and mineral oils. Its nitrile rubber composition provides excellent resistance to these media, ensuring reliable sealing performance and longevity in hydraulic and pneumatic systems.Q: When should the AMS29 Seal be replaced in equipment?

A: Replacement is advisable if signs of wear, hardening, cracking, or persistent leakage become apparent. Routine inspection during scheduled maintenance helps identify when a new seal is necessary to preserve system efficiency and prevent downtime.Q: Where can I source the AMS29 Seal in India?

A: AMS29 Seal is available through manufacturers, retailers, and suppliers across India. These providers supply seals meeting DIN 3771 standards, ensuring consistent quality, and can be found via local industrial distributors or online platforms.Q: What is the benefit of using a high wear resistance seal like AMS29?

A: High wear resistance extends service life and minimizes maintenance interventions. The AMS29's robust construction helps maintain stable hydraulic or pneumatic performance, reducing the risk of leaks and enhancing operational reliability in demanding environments.Q: How does the low compression set feature enhance AMS29's performance?

A: Low compression set means the seal retains its shape and sealing capability over time and under continuous pressure. This characteristic is vital for maintaining effective sealing in dynamic systems, reducing the likelihood of premature seal failure and leakage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AFH - AFHC Seal

Temperature : 30C to +100C

Application : Hydraulic and pneumatic systems

Style : Other, AFHAFHC

Material : NBR (Nitrile Rubber)

Tolerance : 0.05 mm

Shape : Round

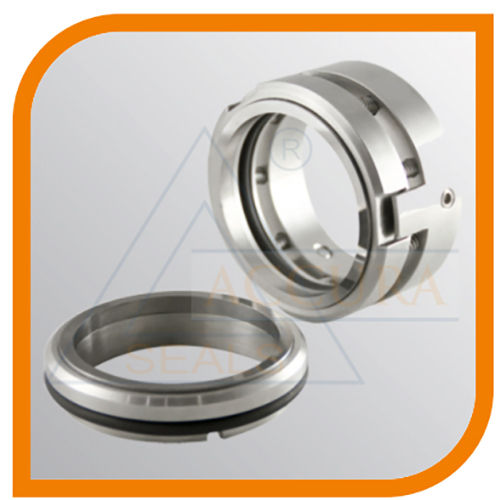

AS60DIN single seal

Temperature : 30C to +120C

Application : DIN Standard Fittings, Hygienic and Sanitary Processing

Style : Other, Single Seal

Material : EPDM/Ethylene Propylene Diene Monomer

Tolerance : 0.02 mm

Shape : Round/ORing

PNL Mechanical seal

Temperature : 20C to 180C

Application : Pumps, Compressors, Mixers, Blowers

Style : Other, Single Spring, Balanced Type

Material : Carbon, Ceramic, Stainless Steel, Nitrile Rubber

Tolerance : 0.05 mm

Shape : Round

AMS13 Seal compliant

Temperature : 150C

Application : Rotating Equipment

Style : Mechanical Seal

Material : Stainless Steel

Tolerance : 0.05 mm

Shape : Circular

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS