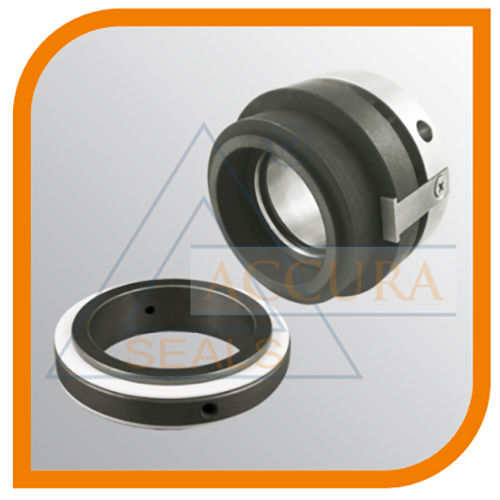

AMS28 Seal

AMS28 Seal Specification

- Hardness

- 855 Shore A

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR)

- Style

- Hydraulic Rod Seal

- Shape

- Round

- Temperature

- -30C to +110C

- Application

- Hydraulic Cylinders

- Color

- Black

- Installation Method

- Press Fit

- Outer Diameter Range

- Up to 200 mm

- Wear Resistance

- High

- Chemical Compatibility

- Mineral Oils, Water-Glycol, some Synthetic Fluids

- Standard

- ISO 6194

- Pressure Resistance

- Up to 40 MPa

About AMS28 Seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction.

- External mounting.

OPERATING LIMITS

- d1= 25 to 175 mm

- p= 15 kg/cm²

- v= 2 m/s

- t= -20 to +200ºC (*)

It can be used in vertical agitators with moderate speeds without the need to apply auxiliary lubrication systems. Adapted to DEBRIS cleaning systems

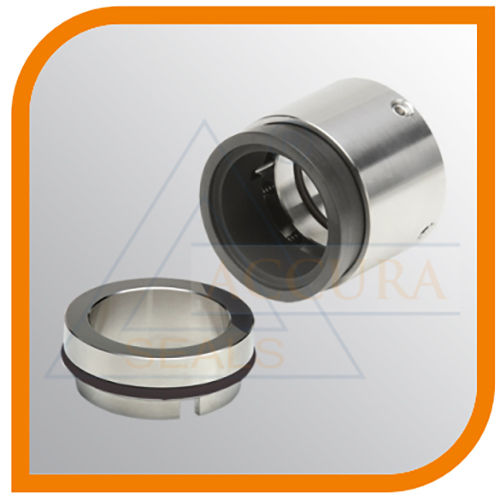

Exceptional Hydraulic Performance

The AMS28 Seal ensures optimum sealing for hydraulic cylinders operating under high pressure and rigorous use. Its advanced design and NBR construction support superior barrier protection, keeping contaminants out while retaining lubricants, for long-term system reliability.

Versatile Material Compatibility

Engineered for compatibility with a broad spectrum of hydraulic fluids, the AMS28 Seal is suitable for systems using mineral oils, water-glycol, and certain synthetic fluids. This versatility makes it an ideal choice for modern hydraulic equipment in various industrial environments.

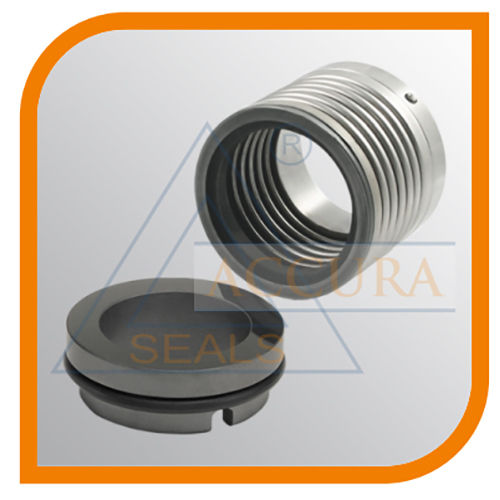

Precision Engineering for Tight Tolerances

Manufactured to ISO 6194 standards and with a close tolerance of 0.05 mm, the AMS28 Seal guarantees a secure fit and stable performance. Its press fit installation method ensures ease of use while maintaining a solid seal even under fluctuating operating conditions.

FAQs of AMS28 Seal:

Q: How is the AMS28 Seal installed in hydraulic cylinders?

A: The AMS28 Seal is designed for a press fit installation, allowing it to be securely positioned within the gland of hydraulic cylinders without specialized tools. Proper lubrication and handling ensure effective sealing and long-term reliability.Q: What fluids is the AMS28 Seal compatible with?

A: This seal is engineered to work with mineral oils, water-glycol, and certain synthetic fluids, making it flexible for a variety of hydraulic system applications. It is important to verify compatibility with specific synthetic fluids before use.Q: When should I consider replacing the AMS28 Seal?

A: Replacement is recommended when there are signs of leakage, visible wear, loss of elasticity, or scheduled maintenance intervals recommended by the equipment manufacturer. Regular inspection ensures maximum efficiency and prevents system failures.Q: Where can the AMS28 Seal be used?

A: This seal is primarily intended for hydraulic cylinders found in industrial machinery, construction equipment, and manufacturing systems. Its robust construction allows it to perform under demanding Indian and international working environments.Q: What are the main benefits of using the AMS28 Seal?

A: The AMS28 Seal offers high wear resistance, robust pressure handling up to 40 MPa, excellent chemical compatibility, and a wide operating temperature range. These qualities collectively extend equipment life, minimize downtime, and enhance operational safety.Q: What standards and tolerances does the AMS28 Seal conform to?

A: It is manufactured according to ISO 6194 standards with a precise tolerance of 0.05 mm, ensuring dependable performance and interchangeability in hydraulic applications.Q: How does the AMS28 Seal perform in extreme temperatures?

A: Constructed from high-quality Nitrile Rubber (NBR), the AMS28 Seal maintains its effectiveness in temperatures ranging from -30C to +110C, enabling reliable operation in both cold and hot environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS14 Seal

Hardness : 6090 Shore A

Material : Nitrile Rubber (NBR)

Application : Hydraulic and pneumatic sealing

Temperature : 30C to +120C

Style : Other, AMS14

Tolerance : 0.1 mm

AMS29 Seal

Hardness : 85 Shore A

Material : Nitrile Rubber (NBR)

Application : Hydraulic and Pneumatic Cylinders

Temperature : 30C to +120C

Style : Other, Hydraulic Rod Seal

Tolerance : 0.05 mm

AMB84 Seal

Hardness : 60 90 Shore A

Material : Nitrile Rubber (NBR)

Application : Hydraulic cylinders, pneumatic cylinders, valves

Temperature : 30C to +120C

Style : Other, Hydraulic Rod Seal

Tolerance : 0.05 mm

AFH - AFHC Seal

Hardness : 705 Shore A

Material : NBR (Nitrile Rubber)

Application : Hydraulic and pneumatic systems

Temperature : 30C to +100C

Style : Other, AFHAFHC

Tolerance : 0.05 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS