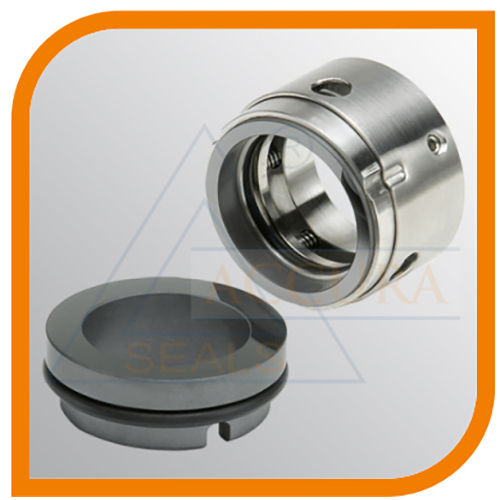

AMS27 multi-spring mechanical seal

AMS27 multi-spring mechanical seal Specification

- Hardness

- 58-60 HRC (faces)

- Tolerance

- 0.02 mm

- Material

- SS316, Carbon, Silicon Carbide, Viton

- Style

- Multi-spring, unbalanced, independent of direction of rotation

- Shape

- Round

- Temperature

- -20C to +180C

- Application

- Pumps, compressors, chemical and pharmaceutical industry

- Seal Arrangement

- Single or back-to-back arrangement

- Face Combination

- Carbon vs. Ceramic/SiC/TC

- Shaft Diameter

- 14 mm to 100 mm

- Spring Material

- SS316

- Speed

- Up to 3000 rpm

- Pressure

- Up to 16 bar

- Rotary Direction

- Independent (bidirectional)

- Media Compatibility

- Acids, alkalis, water, solvents, light hydrocarbons

- Stationary Seat Type

- Lapped Flat / O-ring fitted

About AMS27 multi-spring mechanical seal

CHARACTERISTICS:

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction

- External mounting

OPERATING LIMITS -

- d1= 25 to 160 mm

- p= Vacuum 6 kg/cm²

- v= 2 m/s

- t= -20 to +150ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used.The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application

A multi-spring mechanical seal recommended for vertical stirrers with moderate speeds. The fixed part may have cooling/lubrication systems: flush and/or cooled flange connection

Versatile Media Compatibility

The AMS27 seal is designed to handle a wide range of fluids, including acids, alkalis, solvents, water, and light hydrocarbons. This makes it ideal for use in pumps and compressors across chemical processing, pharmaceutical manufacturing, and industrial fluid handling, where resilience to corrosive and variable media is critical to performance.

Robust Performance Parameters

Withstanding pressures up to 16 bar and speeds up to 3000 rpm, the AMS27 is suitable for high-demand operational environments. Its temperature tolerance from -20C to +180C and selectable face materials (carbon, ceramic, silicon carbide, or tungsten carbide) provide reliable sealing and extended component lifespan, even under fluctuating conditions.

Flexible Installation & Arrangement

Engineered for easy integration, the AMS27 covers shaft diameters from 14 mm to 100 mm and supports both single and back-to-back seal arrangements. The seals design is independent of shaft rotation direction, simplifying installation and minimizing the need for inventory variety, while its multi-spring mechanism ensures consistent face loading.

FAQs of AMS27 multi-spring mechanical seal:

Q: How should the AMS27 mechanical seal be installed for best performance?

A: The AMS27 should be installed according to manufacturer guidelines, ensuring the stationary seat and rotating face are correctly aligned. The seal supports both single and back-to-back configurations, making it suitable for various pump and compressor setups. Care must be taken with seal face cleanliness and correct O-ring fitting during installation.Q: What types of media are compatible with the AMS27 multi-spring seal?

A: The AMS27 is compatible with chemicals such as acids, alkalis, water, solvents, and light hydrocarbons. Its corrosion-resistant materials, including SS316, carbon, silicon carbide, and Viton, allow for reliable operation across a broad spectrum of aggressive and neutral fluids commonly encountered in industrial applications.Q: When is it beneficial to use a back-to-back seal arrangement?

A: A back-to-back arrangement should be considered when sealing hazardous or high-pressure media, or when extra leakage containment is required. This configuration enhances safety, reinforces reliability, and protects equipment in critical chemical and pharmaceutical processing tasks.Q: Where can the AMS27 mechanical seal be applied?

A: The AMS27 is well-suited for pumps and compressors in chemical and pharmaceutical plants, as well as in general industrial applications managing aggressive fluids. Its robust design is especially valued by manufacturers, retailers, and suppliers across India for its versatility and reliability.Q: What is the process to select the correct face combination for different applications?

A: Selection depends on the nature of the media being sealed: carbon-ceramic is typical for clean, non-abrasive fluids; silicon carbide or tungsten carbide options are better for abrasive or high-temperature media. Always consider chemical compatibility, temperature, and pressure requirements when choosing materials.Q: How does the multi-spring design benefit the usage life of the seal?

A: The multi-spring design ensures uniform face loading, which minimizes uneven wear and extends the seals operational life. It also offers better axial movement compensation, crucial in high-speed and variable pressure environments, thus maintaining reliable sealing performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AFH - AFHC Seal

Application : Hydraulic and pneumatic systems

Shape : Round

Material : NBR (Nitrile Rubber)

Style : Other, AFHAFHC

Hardness : 705 Shore A

Tolerance : 0.05 mm

AMS11 Seal compliant

Application : Sealing for rotating equipment

Shape : Round

Material : Stainless Steel

Style : Mechanical Seal

Hardness : Medium

Tolerance : 0.05 mm

AMB85 Seal

Application : Hydraulic and Pneumatic Systems

Shape : Round

Material : Nitrile Rubber (NBR)

Style : Other, Hydraulic Rod Seal

Hardness : 85 Shore A

Tolerance : 0.05 mm

AMS26 Balanced mechanical seal

Application : Pumps, Compressors, Mixers, Agitators

Shape : Round

Material : Carbon, Silicon Carbide, Stainless Steel, EPDM, Viton

Style : Other, Balanced Mechanical Seal

Hardness : 60 to 70 HRC (Seal Faces)

Tolerance : 0.01 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS