ADC40 Double Cartridge

ADC40 Double Cartridge Specification

- Efficiency

- 99.5%

- Orientation

- Vertical

- Sensor Type

- Particulate & Gas Sensors

- Temperature

- Ambient to 55C

- Power Source

- Electric

- Display Type

- LED Status Indicator

- Usage & Applications

- Industrial Air Filtration, Dust Collection

- Measurement

- Air Flow Meter Provided

- Automation Grade

- Semi-Automatic

- Scrubber Type

- Cartridge Based Scrubber

- Instruments Type

- Air Cleaner / Scrubber

- Air Flow

- 4000 m/h

- Product Type

- Double Cartridge

- Material

- Mild Steel (Powder Coated)

- Cooling System

- Air Cooled

- Noise Level

- <70 dB

- Reactor Thickness

- 5 mm

- Processing Time

- 24 Hours Continuous

- Capacity

- 4000 m/h

- Voltage

- 220-240 V AC

- Weight

- 95 kg

- Dimension (L*W*H)

- 810 x 750 x 1480 mm

- Surface

- Powder Coated Finish

- Filter Material

- Nano Fiber/Polyester

- Color

- Blue/Grey

- Mounting Type

- Floor Standing

- Static Pressure

- 120 mm WG

- Power Consumption

- 2.2 kW

- Dust Collection

- Removable Tray

- Filtration Area

- 40 m

- Fan Power

- 3.0 HP

- Inlet Size

- 200 mm

- Number of Cartridges

- 2

- Pre-filter Type

- Washable

- Discharge Option

- Bottom Hopper

About ADC40 Double Cartridge

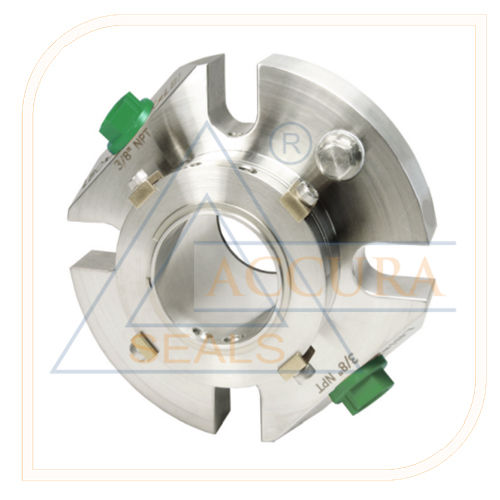

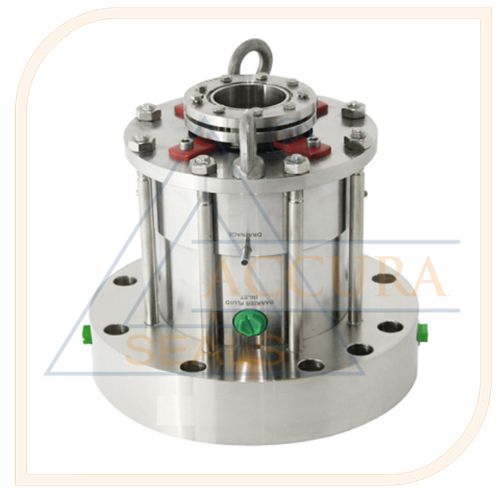

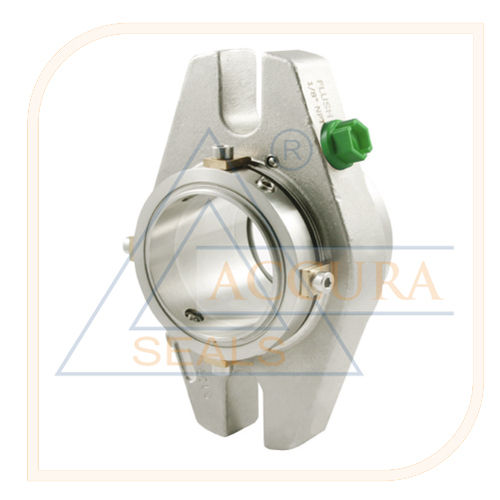

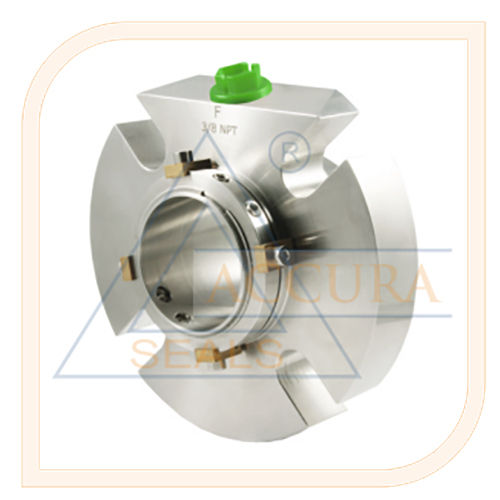

- Balanced.

- Multispring.

- Not dependent on the rotation direction.

- Barrier fluid connections.

- d= 25 to100 mm = p= 25 kg/cm

- v= 16 m/s t= -15 to +200C (*)

(*) The temperature resistance depends on the material of the secondary seals used.

Advanced Filtration Technology

Featuring nano fiber/polyester cartridges and a washable pre-filter, the ADC40 delivers superior particulate and gas removal. Its 99.5% efficiency is ideal for manufacturing, workshops, or industrial settings, reliably meeting demanding air quality standards.

Designed for Endurance and Convenience

Built to run continuously for 24 hours, the units mild steel, powder-coated construction resists wear. The removable dust tray and bottom hopper make routine cleaning easy, while semi-automatic controls and an LED indicator enhance usability and oversight.

Versatile and User Friendly

With a compact footprint and floor-standing design, this air cleaner is easy to install across various sites in India. Features such as ambient-to-55C operating temperature, air-cooled system, and integrated air flow measurement ensure safe and flexible operation.

FAQs of ADC40 Double Cartridge:

Q: How does the ADC40 Double Cartridge filter industrial air so effectively?

A: The ADC40 Double Cartridge uses two nano fiber/polyester filters with a combined filtration area of 40 m, capturing up to 99.5% of dust and particulates. Its washable pre-filter also helps extend cartridge life by trapping larger debris, ensuring long-term performance.Q: What kind of industries and environments can benefit from the ADC40?

A: This unit is designed for industrial air filtration, suitable for factories, manufacturing workshops, and process industries in India. Its robust design and high air flow capacity (4000 m/h) make it effective for dust collection and air scrubbing in demanding applications.Q: When should the dust collection tray and filters be maintained or replaced?

A: The removable dust tray should be emptied regularly based on dust load, while the washable pre-filter can be cleaned as necessary. Cartridges typically require replacement when efficiency drops or as indicated by the LED status or particulate sensors.Q: Where is the ADC40 typically installed and what space does it require?

A: The floor-standing design allows the ADC40 to be installed in a range of industrial settings. With dimensions of 810 x 750 x 1480 mm, it fits comfortably in most workshop or plant locations requiring effective local air filtration.Q: What is the process for air filtration and dust collection in this unit?

A: Contaminated air enters through a 200 mm inlet, passes through the washable pre-filter and cartridge filters, where dust and particulates are captured. Clean air is discharged, while dust is deposited into the bottom hopper and collected in the removable tray.Q: How do users benefit from the ADC40s automation and monitoring features?

A: Semi-automatic controls, an LED status indicator, and integrated sensors (for air flow and particulate/gas levels) allow for easy monitoring and operation, helping users to optimize air quality with minimal effort and reduce maintenance downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cartridge Category

ADC80 Double Cartridge

Product Type : Double Cartridge Air Purifier

Material : Stainless Steel body, Highgrade Polycarbonate Cartridge

Instruments Type : Air Filtration/Scrubber Unit

Usage & Applications : Laboratory air filtration, Chemical process exhaust purification, VOC scrubbing, Airborne contaminant reduction

Sensor Type : Optical particle sensor

Surface : Polished anticorrosive finish

ASC80 Single Cartridge

Product Type : Single Cartridge Dust Collector

Material : Mild Steel

Instruments Type : Dust Collector

Usage & Applications : Laboratory and smallscale industrial dust filtration

Sensor Type : Differential Pressure Sensor (Optional)

Surface : Powder Coated

ASC211A-FD Single Cartridge

Product Type : Single Cartridge Dust Collector

Material : Mild Steel

Instruments Type : Air Filtration Unit

Usage & Applications : Industrial Dust Collection, Fume Extraction

Sensor Type : Differential Pressure Sensor

Surface : Powder Coated

ASC40-F ANSI Single Cartridge

Product Type : ASC40F ANSI Single Cartridge

Material : Stainless Steel

Instruments Type : Single Cartridge

Usage & Applications : Industrial Applications

Sensor Type : Temperature Sensor

Surface : Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS