ASC211A-FD Single Cartridge

ASC211A-FD Single Cartridge Specification

- Sensor Type

- Differential Pressure Sensor

- Automation Grade

- Semi-Automatic

- Measurement

- Particulate Concentration

- Scrubber Type

- Dry Scrubber

- Instruments Type

- Air Filtration Unit

- Display Type

- Indicator Light

- Temperature

- Up to 55C

- Air Flow

- 1500 m/hr

- Power Source

- Electric

- Orientation

- Vertical

- Efficiency

- >99%

- Usage & Applications

- Industrial Dust Collection, Fume Extraction

- Product Type

- Single Cartridge Dust Collector

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- <75 dB(A)

- Processing Time

- Continuous

- Capacity

- 1000 - 2000 m/hr

- Voltage

- 230V AC

- Weight

- Approximately 90 kg

- Dimension (L*W*H)

- 650 x 650 x 1500 mm

- Surface

- Powder Coated

- Mobility

- Fixed

- Colour

- Grey/Blue

- Filter Cleaning Method

- Pulse Jet Cleaning

- Dust Discharge System

- Drawer Type

- Mounting

- Standalone

- Inlet & Outlet Diameter

- 150 mm

- Number of Cartridges

- 1

- Cartridge Material

- Polyester

- Power Consumption

- 1.5 kW

- Filtration Stage

- Single Stage

- Control Panel

- Included

- Installation Method

- Floor Mounted

About ASC211A-FD Single Cartridge

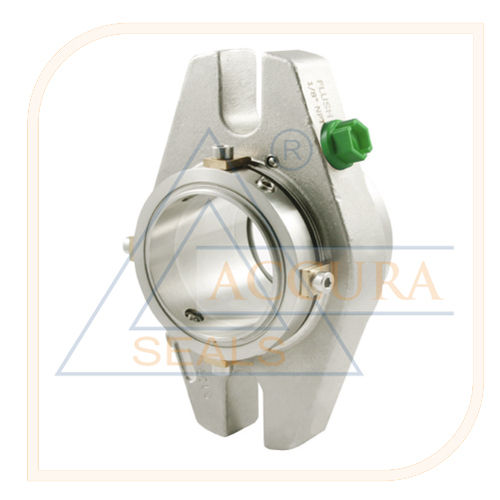

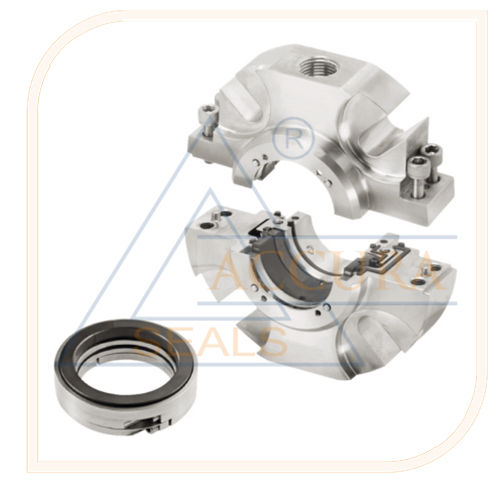

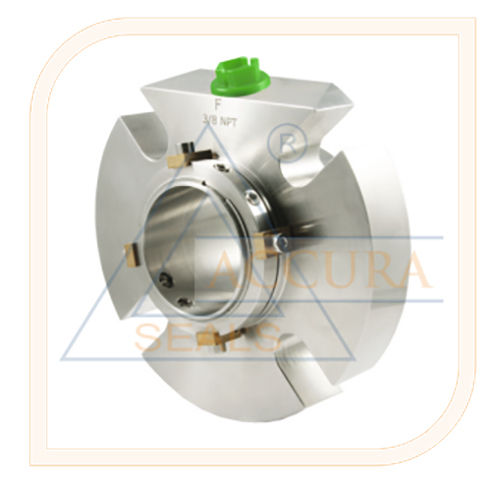

- Balanced.

- Multispring.

- Not dependent on the rotation direction.

- Stuffing box gland shape.

- Flush and drain connections.

- d=25 to70mm p= 20 kg/cm

- v= 11.2 m/s t=-15 to +200C (*)

Superior Filtration and Reliable Operation

Engineered for industrial environments, the ASC211A-FD efficiently removes airborne dust and fumes using a robust polyester cartridge. Its pulse jet cleaning maintains optimal filter performance, while the single-stage system delivers consistent results. With a compact, vertical orientation and powder-coated finish, maintenance is effortless, and durability is assured.

User-Centric Control and Flexibility

A built-in indicator light display and semi-automatic operation make monitoring and control straightforward. The unit runs on standard 230V AC power and features a user-friendly dust drawer discharge system. Its fixed, standalone design allows easy floor installation in any industrial setting, ensuring safety and stability.

FAQs of ASC211A-FD Single Cartridge:

Q: How is the ASC211A-FD Single Cartridge unit installed?

A: The ASC211A-FD is designed for floor mounting, offering a stable, fixed placement. Its compact size and standalone configuration allow easy installation in industrial spaces without the need for complex mounting hardware.Q: What method is used for filter cleaning in this dust collector?

A: The ASC211A-FD employs a pulse jet cleaning method, which uses jets of air to periodically clean the polyester filter cartridge. This ensures continuous filtration efficiency and extends the service life of the filter.Q: When is the dust drawer discharged, and how easy is the process?

A: The dust drawer should be emptied as indicated by operational monitoring or routine schedules, depending on dust load. The drawer-type system makes disposal simple and minimizes direct contact with collected particulates.Q: Where can this air filtration unit be used?

A: This unit is suitable for industrial environments such as manufacturing plants, workshops, and locations that require efficient dust or fume extraction. It is ideal for applications involving dry particulate matter.Q: What are the primary benefits of using the ASC211A-FD in industrial settings?

A: The ASC211A-FD offers high dust collection efficiency (>99%), quiet operation (<75 dB(A)), ease of maintenance, and dependable continuous processing. Its semi-automatic features reduce manual intervention, enhancing productivity and workplace safety.Q: How does the control panel assist in operation?

A: The integrated control panel features indicator lights for status monitoring, making it simple for operators to gauge system health and respond promptly to maintenance needs or operational changes.Q: What types of materials can this air filtration unit efficiently handle?

A: The ASC211A-FD is designed for handling industrial airborne dust and fumes, specifically dry particulates up to a temperature of 55C, as found in various manufacturing and process plants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cartridge Category

ADC80 Double Cartridge

Product Type : Double Cartridge Air Purifier

Usage & Applications : Laboratory air filtration, Chemical process exhaust purification, VOC scrubbing, Airborne contaminant reduction

Surface : Polished anticorrosive finish

Material : Stainless Steel body, Highgrade Polycarbonate Cartridge

Instruments Type : Air Filtration/Scrubber Unit

Efficiency : 99.97% particulate removal

ASC90 Single Cartridge

Product Type : Single Cartridge Air Scrubber

Usage & Applications : Air purification in laboratories, hospitals, and industrial spaces

Surface : Powder coated, corrosionresistant

Material : Mild Steel, Powder Coated

Instruments Type : Air Pollution Control Equipment

Efficiency : Up to 99%

ASC50-F Single Cartridge

Product Type : Single Cartridge Air Scrubber

Usage & Applications : Laboratory Fume Extraction, Chemical Air Treatment

Surface : Powder Coated

Material : Galvanized Iron (GI)

Instruments Type : Air Pollution Control Equipment

Efficiency : 95%

ASC40-F Single Cartridge

Product Type : Single Cartridge Seal

Usage & Applications : Industrial machinery and pumps

Surface : Precision Finished

Material : Stainless Steel

Instruments Type : Mechanical Seal

Efficiency : High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS