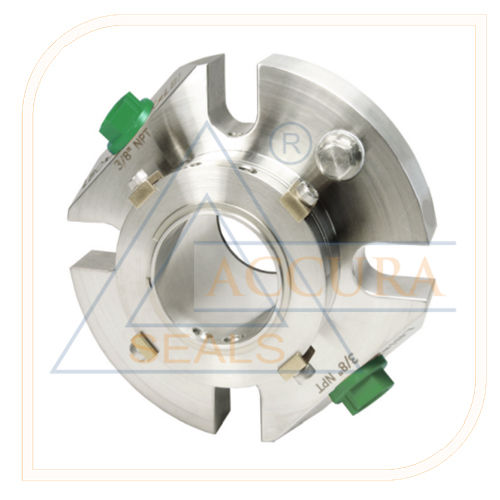

ADC80 Double Cartridge

ADC80 Double Cartridge Specification

- Power Source

- Electric, Plug-in

- Usage & Applications

- Laboratory air filtration, Chemical process exhaust purification, VOC scrubbing, Airborne contaminant reduction

- Scrubber Type

- Double cartridge activated carbon

- Instruments Type

- Air Filtration/Scrubber Unit

- Air Flow

- 850 m/hr

- Display Type

- Digital LED operational display

- Automation Grade

- Semiautomatic

- Orientation

- Vertical cartridge mount

- Efficiency

- 99.97% particulate removal

- Measurement

- Air quality (inbuilt sensor)

- Sensor Type

- Optical particle sensor

- Temperature

- Operational range: 0C to 65C

- Product Type

- Double Cartridge Air Purifier

- Material

- Stainless Steel body, High-grade Polycarbonate Cartridge

- Cooling System

- Integrated Heat Dissipation Fins

- Noise Level

- 67 dB

- Reactor Thickness

- 8 mm

- Processing Time

- Instantaneous (Continuous flow)

- Capacity

- 80 Litres/hour cartridge throughput

- Voltage

- 220-240 V AC

- Weight

- 38 kg

- Dimension (L*W*H)

- 580 x 260 x 680 mm

- Surface

- Polished anti-corrosive finish

- Operating Humidity

- 10 - 85% RH

- Filter Media Type

- Activated carbon with HEPA stage

- Maintenance

- Tool-free quick open access

- Color

- Metallic grey & blue

- Control System

- Programmable timer & overload protection

- Mounting

- Table-top/Bench compatible

- Emission Standards

- Meets local safety and emission regulations

- Installation

- Plug-and-play

- Input Connection

- " standard pipe coupling

- Cartridge Life

- Up to 3200 hours

- Power Consumption

- 120 W

About ADC80 Double Cartridge

- Balanced.

- Multispring.

- Not dependent on the rotation direction.

- Barrier fluid connections.

- d= 40to220mm_ p= 16 kg/cm

- v= 5m/s t=-40 to +300C (*)

The internal structure "Back to Back" is continuously lubricated by a liquid barrier, which must be pressurized between 1.5 and 2 kg/cm above the working fluid.

Flange connection for steel vessels DIN 28141, shaft end for steel vessels DIN 28154 and DIN 28136 glass-li-ned vessels.

Advanced Double Cartridge Filtration

The ADC80 utilizes a powerful combination of activated carbon and HEPA filters, ensuring ultra-high efficiency in removing particulates and airborne chemicals. Its double cartridge system supports continuous operation and processes large air volumes up to 850 m3/hr, meeting the rigorous demands of laboratories and industrial applications safely and efficiently.

Effortless Maintenance, Long Cartridge Life

Designed with tool-free quick open access, the ADC80 simplifies routine maintenance. The high-grade polycarbonate cartridges boast a lifespan of up to 3200 hours, reducing interruptions and replacement costs while sustaining consistent purification performance for extended operational periods.

Plug-and-Play Convenience and Robust Control

Installation is seamless thanks to the table-top or bench-mountable, plug-in design and standard pipe connection. With a digital LED display, programmable timer, and overload protection, users can monitor, control, and protect the unit with ease, optimizing workplace safety and efficiency.

FAQ's of ADC80 Double Cartridge:

Q: How does the ADC80 Double Cartridge system improve air quality in laboratories?

A: The ADC80 employs a double-stage filtration process combining activated carbon and HEPA media, capturing 99.97% of particulates along with VOCs and chemical contaminants. This results in cleaner, safer air for laboratory personnel and sensitive experiments.Q: What is involved in maintaining the ADC80, and how frequently is it required?

A: Maintenance is minimal-thanks to a tool-free quick open design. Cartridges last up to 3200 hours under standard conditions, after which simple, hands-on replacement ensures your air stays fresh with little downtime.Q: Where can the ADC80 be installed, and what are the mounting options?

A: The ADC80 is designed for versatility. It can be easily mounted on laboratory benches or used as a table-top unit, fitting various workspace layouts without permanent modifications.Q: When should I replace the filter cartridges in the ADC80 Air Filtration Unit?

A: Cartridges should be replaced after approximately 3200 operating hours, or sooner if air quality indicators or the inbuilt sensor suggest diminished efficiency. Regular checks of the digital LED panel will alert you to service needs.Q: What benefits does the programmable timer and overload protection provide?

A: The programmable timer lets users automate operation, boosting energy efficiency and convenience. Overload protection safeguards the unit and environment from electrical accidents, ensuring long-term, reliable performance.Q: How is the ADC80 installed, and what is required for setup?

A: Installation is straightforward: simply connect the 34" standard pipe coupling, plug the unit into a standard 220-240 V AC source, and it's ready for use. No special tools or complex wiring are necessary.Q: What types of air contaminants can the ADC80 efficiently remove?

A: The ADC80 is effective against a wide range of airborne pollutants including laboratory vapors, chemical process exhausts, VOCs, and fine particulates, making it optimal for laboratory, healthcare, and industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cartridge Category

ADC40 Double Cartridge

Surface : Powder Coated Finish

Instruments Type : Air Cleaner / Scrubber

Usage & Applications : Industrial Air Filtration, Dust Collection

Product Type : Double Cartridge

Material : Mild Steel (Powder Coated)

Automation Grade : SemiAutomatic

ASC25 Single Cartridge

Surface : Powder Coated

Instruments Type : Dust Collector

Usage & Applications : Industrial Air Filtration, Dust Collection, Workshop Use

Product Type : Single Cartridge Dust Collector

Material : Mild Steel

Automation Grade : SemiAutomatic

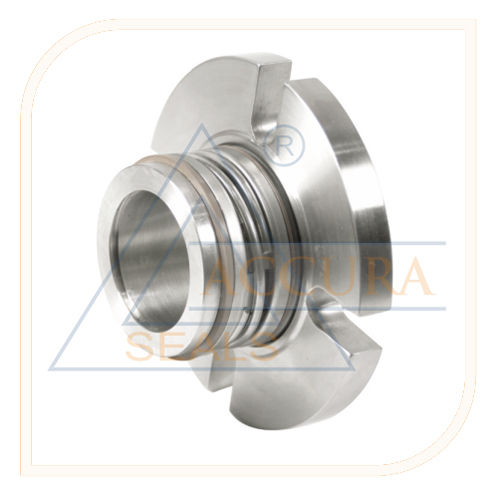

ASC10 Single Cartridge

Surface : Polished

Instruments Type : Mechanical Seal

Usage & Applications : Industrial sealing applications

Product Type : Mechanical Seal

Material : Stainless Steel

Automation Grade : Manual

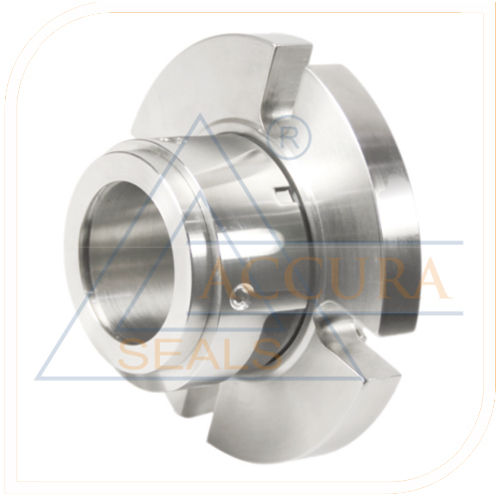

ADC38 Double Cartridge

Surface : Polished

Instruments Type : Double Cartridge

Usage & Applications : Industrial

Product Type : ADC38 Double Cartridge

Material : Stainless Steel

Automation Grade : SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS