AWS10B Seal

AWS10B Seal Specification

- Feature

- High abrasion resistance, excellent elasticity

- Hardness

- 705 Shore A

- Tolerance

- 0.05 mm

- Material

- Polyurethane (PU)

- Style

- AWS10B

- Shape

- Round

- Temperature

- -35C to +100C

- Application

- Hydraulic and pneumatic sealing in cylinders

- Color

- Blue

- Size Range

- 10 mm to 200 mm OD

- Packaging

- Individually packed

- Compression Set

- Low

- Installation Type

- Snap-in

- Surface Finish

- Smooth

- Pressure Resistance

- up to 400 Bar

- Chemical Resistance

- Good resistance to mineral oils and greases

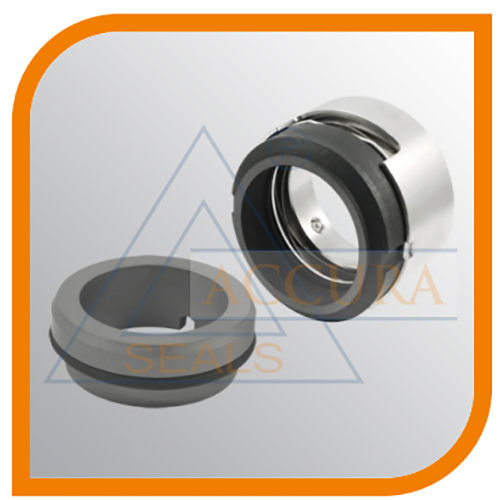

About AWS10B Seal

- Balanced.

- System attached to the shaft by allen screws.

- Not dependent on the rotation direction

- d1= 14 to 100 mm

- p= 25 kg/cm²

- v= 20 m/s

- t= -50 to +220ºC (*)

The casing can incorporate a pumping ring to reduce the temperature between the contact surfaces and facilitate the barrier fluid movement in the case of double mounting (AWS10B-F).

Superior Pressure and Abrasion Resistance

Designed to handle pressure up to 400 Bar, the AWS10B Seal is engineered for challenging hydraulic and pneumatic environments. Its high abrasion resistance ensures durability, even with repeated motion, making it a preferred choice for cylinder sealing applications requiring reliability and long-term performance.

Chemical and Temperature Tolerance for Versatile Applications

Constructed using premium polyurethane (PU), the AWS10B Seal offers robust resistance to mineral oils and greases, paired with temperature flexibility from -35C to +100C. This combination makes it suitable for diverse operational settings, particularly in industrial fluid handling systems.

FAQ's of AWS10B Seal:

Q: How is the AWS10B Seal installed in hydraulic and pneumatic cylinders?

A: The AWS10B Seal features a convenient snap-in installation design. This allows for quick and secure fitting into both hydraulic and pneumatic cylinders, requiring minimal tools or modification during the assembly process.Q: What is the recommended operating temperature range for the AWS10B Seal?

A: The seal provides optimal performance within a temperature range of -35C to +100C, making it suitable for applications exposed to cold or hot fluid environments.Q: Where can the AWS10B Seal be used?

A: The AWS10B Seal is ideal for use in hydraulic and pneumatic sealing applications, specifically in cylinder-based systems. Typical installation sites include industrial machinery, automation equipment, and various fluid-based power transmission systems.Q: What benefits does the AWS10B Seal offer compared to other sealing solutions?

A: Key benefits include high pressure resistance (up to 400 Bar), excellent abrasion resistance, low compression set for longevity, and reliable chemical resilience against mineral oils and greases. Its smooth surface and quality packaging also ensure easy handling during installation.Q: How does the AWS10B Seal ensure dimensional accuracy?

A: With a machining tolerance of 0.05 mm, the AWS10B Seal delivers precise fitting in cylinder grooves. This accuracy minimizes leakage risks and contributes to the overall effectiveness of the seal.Q: When should the AWS10B Seal be replaced?

A: Replacement should be considered when there are signs of visible wear, reduced sealing efficiency, or when recommended maintenance schedules dictate, especially in demanding operating conditions.Q: What process is used to manufacture the AWS10B Seal?

A: The AWS10B Seal is manufactured using high-quality polyurethane (PU) and strict quality controls, ensuring consistent hardness (705 Shore A) and surface finish. Each seal is inspected and individually packed for supply by manufacturers, retailers, or suppliers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS29 Seal

Style : Other, Hydraulic Rod Seal

Temperature : 30C to +120C

Shape : Round/ORing

Tolerance : 0.05 mm

Material : Nitrile Rubber (NBR)

Application : Hydraulic and Pneumatic Cylinders

AMB84 Seal

Style : Other, Hydraulic Rod Seal

Temperature : 30C to +120C

Shape : Round

Tolerance : 0.05 mm

Material : Nitrile Rubber (NBR)

Application : Hydraulic cylinders, pneumatic cylinders, valves

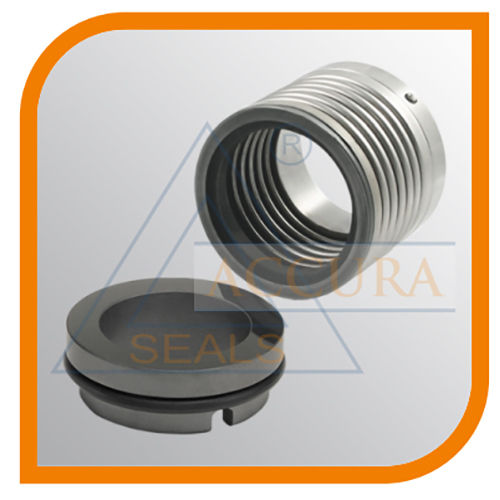

AMS13 Seal compliant

Style : Mechanical Seal

Temperature : 150C

Shape : Circular

Tolerance : 0.05 mm

Material : Stainless Steel

Application : Rotating Equipment

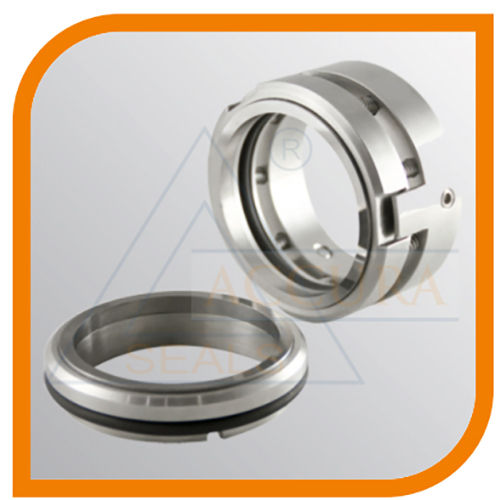

AMS15D Double seal

Style : Other, Double seal

Temperature : Hightemperature resistance

Shape : Circular

Tolerance : Precise fit and high tolerance

Material : Metal and rubber composite

Application : Seal for industrial pumps

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS