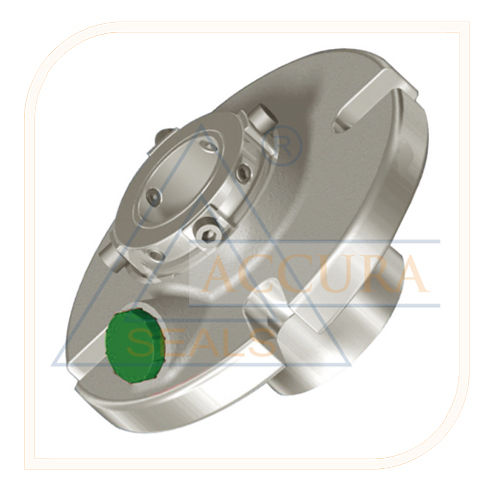

ASC38-FQ Single Cartridge

ASC38-FQ Single Cartridge Specification

- Power Source

- Electric

- Temperature

- Ambient to 55C

- Measurement

- Direct Flow Measurement

- Scrubber Type

- Dry Scrubber

- Usage & Applications

- Fume extraction, Air Pollution Control, Industrial Dust Collection

- Orientation

- Vertical

- Display Type

- Analog Indicator

- Efficiency

- 99% Filtration Efficiency

- Sensor Type

- Particulate Sensor

- Instruments Type

- Industrial Air Purifier

- Automation Grade

- Semi-Automatic

- Air Flow

- Up to 1500 m/h

- Product Type

- Single Cartridge Filter Unit

- Material

- Mild Steel (Powder Coated)

- Cooling System

- Air Cooled

- Noise Level

- Less than 75 dB

- Reactor Thickness

- 3 mm

- Processing Time

- Continuous Operation

- Capacity

- Up to 1500 m/h

- Voltage

- 220-240 V

- Weight

- 48 kg

- Dimension (L*W*H)

- 600 x 550 x 1200 mm

- Surface

- Powder Coated

- Mobility

- Caster Wheels for Easy Movement

- Control Panel

- On/Off Switch with Indicator

- Filter Type

- Cartridge Filter

- Application Area

- Welding Fume, Soldering Workshop, Laser Cutting

- Number of Cartridges

- 1

- Fan Type

- Centrifugal Fan

- Colour

- Blue And White

- Dust Collection

- Manual Dust Discharge

- Mounting Type

- Floor Standing

- Cleaning System

- Manual Cleaning

About ASC38-FQ Single Cartridge

- Balanced.

- Welded Metal bellows.

- Not dependent on the rotation direction.

- Flushing and quenching connections.

- d= 25 to80mm_ p= 20 kg/cm

- v= 25 m/s t= -15 to +200C (*)

- From 25 mm to 65 mm: 1/4 NPT.

- From 70 mm to 80 mm: 3/8 NPT.

Reliable Air Purification for Industrial Spaces

ASC38-FQ Single Cartridge air purifier is engineered for demanding industrial environments, effectively capturing welding fumes, soldering particulates, and laser-cut dust. Its high-efficiency filtration safeguards air quality, supporting compliance with workplace standards. The semi-automatic system with direct flow and particulate measurement ensures operational control and real-time monitoring.

Practical Features Boost Productivity

Mobility is simplified by sturdy caster wheels, allowing effortless repositioning as worksite needs evolve. The manual dust discharge and cleaning system minimize maintenance interruptions, while the analog indicator delivers clear operational status for swift adjustment. Powder-coated mild steel ensures durability and resistance to harsh conditions, making this unit a reliable investment for manufacturers, retailers, and suppliers.

FAQ's of ASC38-FQ Single Cartridge:

Q: What type of filter does the ASC38-FQ Single Cartridge use?

A: The ASC38-FQ uses a cartridge filter designed for effective removal of fumes and fine particulates commonly encountered in welding, soldering, and laser cutting operations.Q: How do I clean and maintain the ASC38-FQ unit?

A: Cleaning is manual, requiring periodic dust discharge and maintenance of the cartridge filter to sustain 99% filtration efficiency. Instructions for proper cleaning procedures are provided with the unit.Q: Where is this air purifier best installed?

A: The ASC38-FQ is intended for use in industrial areas such as welding shops, soldering workshops, and laser cutting stations. Its floor-standing design with caster wheels provides flexible placement on solid, level surfaces.Q: What benefits does the centrifugal fan offer?

A: The centrifugal fan delivers powerful airflow up to 1500 m3/h while maintaining noise levels below 75 dB, ensuring effective extraction and a quieter working environment.Q: How does the manual cleaning system work?

A: The manual cleaning system involves physically removing dust from the discharge area and cleaning the filter cartridge as needed, helping maintain high filtration efficiency and prolonging filter life.Q: When should I perform maintenance on the ASC38-FQ?

A: Maintenance should be performed according to operational hours and exposure levels. Frequent cleaning may be needed in high-dust environments, with visual checks aided by the analog indicator.Q: What is the application range for the ASC38-FQ Single Cartridge?

A: The unit is suitable for fume extraction, air pollution control, and industrial dust collection in sectors requiring dry scrubbing and continuous air filtration, accommodating ambient temperatures up to 55C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cartridge Category

ADC90 Double Cartridge

Instruments Type : Dust Collector

Noise Level : Below 80 dB

Efficiency : Up to 99%

Material : Mild Steel

Dimension (L*W*H) : 950 x 650 x 1650 mm

Usage & Applications : Industrial Air Filtration, Dust Removal in Workshops, Factories, Woodworking, Pharma, Textile, etc.

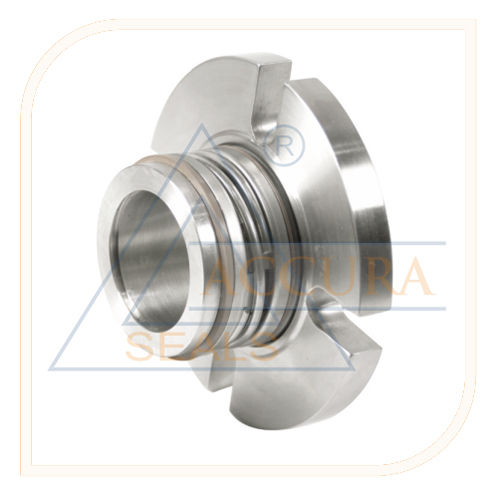

ASC50-F Single Cartridge

Instruments Type : Air Pollution Control Equipment

Noise Level : Below 70 dB

Efficiency : 95%

Material : Galvanized Iron (GI)

Dimension (L*W*H) : 500 x 320 x 350 mm

Usage & Applications : Laboratory Fume Extraction, Chemical Air Treatment

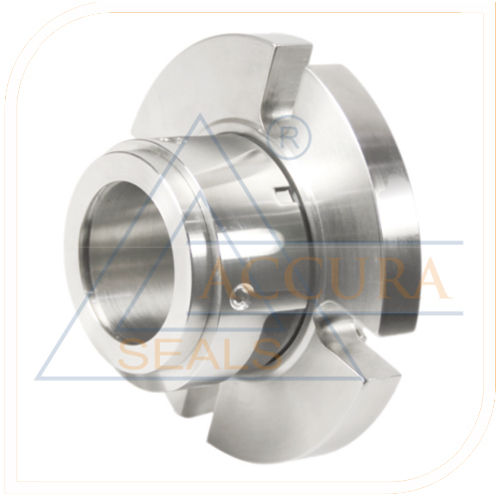

ASC25 Single Cartridge

Instruments Type : Dust Collector

Noise Level : Less than 70 dB(A)

Efficiency : Up to 99%

Material : Mild Steel

Dimension (L*W*H) : 800 x 470 x 1500 mm

Usage & Applications : Industrial Air Filtration, Dust Collection, Workshop Use

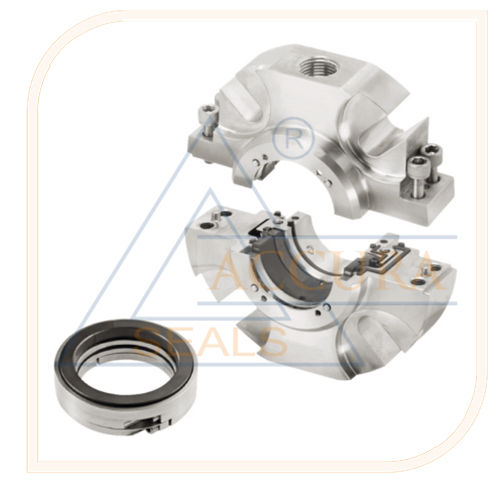

ASC10 Single Cartridge

Instruments Type : Mechanical Seal

Noise Level : Low

Efficiency : High sealing efficiency

Material : Stainless Steel

Dimension (L*W*H) : Standard dimensions as per ASC10 specifications

Usage & Applications : Industrial sealing applications

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS