ADC90 Double Cartridge

ADC90 Double Cartridge Specification

- Temperature

- Up to 60C

- Scrubber Type

- Cartridge Type

- Orientation

- Vertical

- Instruments Type

- Dust Collector

- Efficiency

- Up to 99%

- Sensor Type

- Particulate Sensor

- Power Source

- Electric

- Automation Grade

- Semi-Automatic

- Display Type

- Analog

- Measurement

- Particulate Matter

- Usage & Applications

- Industrial Air Filtration, Dust Removal in Workshops, Factories, Woodworking, Pharma, Textile, etc.

- Air Flow

- 2200 m/hr

- Product Type

- Double Cartridge Dust Collector

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 80 dB

- Reactor Thickness

- 2 mm

- Processing Time

- Continuous Operation

- Capacity

- 90 liters

- Voltage

- 220V / 50 Hz

- Weight

- Approx. 180 kg

- Dimension (L*W*H)

- 950 x 650 x 1650 mm

- Surface

- Powder Coated

- Filter Surface Area

- 36 m (approx.)

- Inlet/Outlet Size

- 250 mm

- Mobility

- Castor Wheels for Easy Movement

- Static Pressure

- 2200 Pa

- Motor Power

- 2.2 kW

- Suitable Dust Types

- Powder, Fume, Fine Particles

- Corrosion Protection

- Yes

- Cleaning Method

- Reverse Air Jet Pulse

- Number of Cartridge Filters

- 2

- Installation

- Floor Mounted

- Filter Material

- Cellulose/Polyester Blend

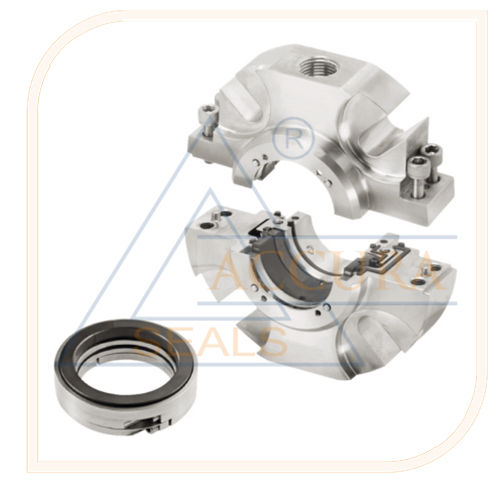

About ADC90 Double Cartridge

- Balanced.

- Multispring.

- Not dependent on the rotation direction.

- Barrier fluid connections.

- p= 25 kg/cm

- v= 16 m/s

- t= -15 to +200C (*)

The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

DESCRIPTION:

Exceptional Filtration Efficiency

With a high-quality cellulose/polyester filter blend over 36 m surface area, the ADC90 ensures reliable removal of fine particles, dust, and fumes with efficiency up to 99%. Its reverse air jet pulse cleaning method maintains optimal filter performance, making it highly effective for continuous industrial use.

Robust and Versatile Design

Constructed from mild steel with powder coating for added durability and corrosion resistance, the ADC90 features castor wheels for mobility and a compact vertical orientation. This makes it adaptable for various installations in workshops, factories, and other industrial settings, maximizing both protection and productivity.

FAQs of ADC90 Double Cartridge:

Q: How does the ADC90 Double Cartridge Dust Collector maintain filter performance during continuous operation?

A: The ADC90 utilizes a reverse air jet pulse cleaning system that regularly removes accumulated dust from the filter surfaces. This self-cleaning process ensures that the filter media remains unclogged, supporting uninterrupted and efficient operation in industrial environments.Q: What types of dust and particles is the ADC90 suitable for collecting?

A: This dust collector is designed to effectively handle powder, fumes, and fine particles commonly found in factories, woodworking units, pharmaceutical settings, textile plants, and other industrial applications.Q: When should I perform routine maintenance on the ADC90?

A: Although the reverse air jet pulse cleaning system reduces manual cleaning, it is recommended to inspect the filters, inlets, and outlets periodically. Maintenance schedules may vary based on the dust load, but a monthly inspection is typically adequate for optimal operation.Q: Where can the ADC90 Double Cartridge Dust Collector be installed?

A: The ADC90 is designed for floor-mounted installation and is equipped with castor wheels, making it easy to move and position within workshops, production areas, or any dust-prone industrial sites.Q: What is the benefit of using a cellulose/polyester blended filter material?

A: The cellulose/polyester blend provides a balance of high filtration efficiency and durability. This combination captures a wide range of particle sizes while withstanding the mechanical stress of pulse cleaning, extending filter life and maintaining performance.Q: How does the ADC90 ensure safety and durability in challenging environments?

A: Constructed from mild steel and coated with a protective powder finish, the ADC90 offers excellent resistance to corrosion. It is also equipped with protective features, such as static pressure monitoring and sturdy construction, for reliable long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cartridge Category

ASC50-F Single Cartridge

Material : Galvanized Iron (GI)

Noise Level : Below 70 dB

Dimension (L*W*H) : 500 x 320 x 350 mm

Instruments Type : Air Pollution Control Equipment

Efficiency : 95%

Surface : Powder Coated

ASC90 Single Cartridge

Material : Mild Steel, Powder Coated

Noise Level : Less than 75 dB

Dimension (L*W*H) : 500mm x 450mm x 1200mm

Instruments Type : Air Pollution Control Equipment

Efficiency : Up to 99%

Surface : Powder coated, corrosionresistant

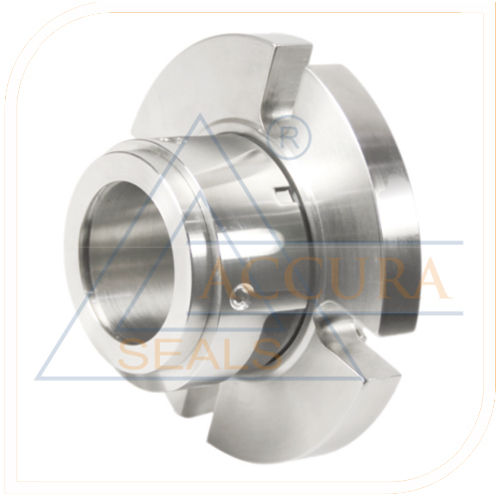

ASC10 Single Cartridge

Material : Stainless Steel

Noise Level : Low

Dimension (L*W*H) : Standard dimensions as per ASC10 specifications

Instruments Type : Mechanical Seal

Efficiency : High sealing efficiency

Surface : Polished

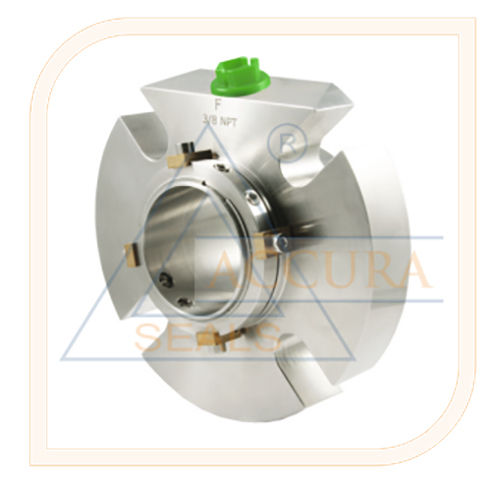

ASC40-F Single Cartridge

Material : Stainless Steel

Noise Level : Low

Dimension (L*W*H) : Compact Design

Instruments Type : Mechanical Seal

Efficiency : High

Surface : Precision Finished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS