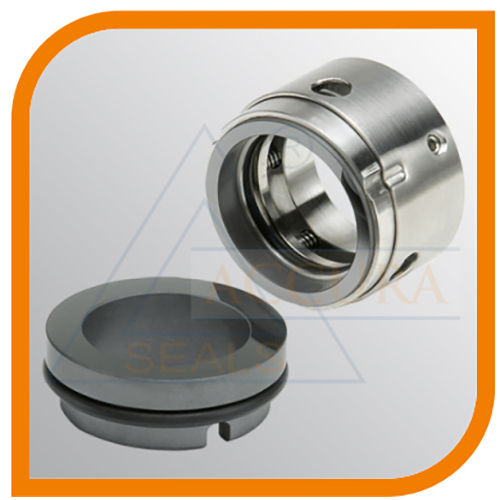

AS40C Single mechanical seal

AS40C Single mechanical seal Specification

- Tolerance

- 0.01 mm

- Hardness

- 60-70 HRC

- Material

- Carbon, Ceramic, Silicon Carbide, Stainless Steel

- Style

- Single Mechanical Seal

- Shape

- Round

- Temperature

- -20C to 180C

- Application

- Water Pump, Industrial Pump, Rotating Equipment

- Speed

- Up to 3000 RPM

- Pressure

- Up to 12 bar

- Shaft Diameter Range

- 12mm to 100mm

- Elastomer Option

- NBR, EPDM, Viton

- Direction of Rotation

- Bidirectional

- Suitable Media

- Water, Oils, Mild Acids, Light Chemicals

- Installation

- Single spring, easy to install

About AS40C Single mechanical seal

CHARACTERISTICS:

- Unbalanced.

- System attached to the shaft by allen screws.

- Dependent on the rotation direction.

- Single cylindrical spring

- d1= 20 to 100 mm

- p= 12 kg/cm²

- v= 15 m/s

- t= -20 to +200ºC (*)

(*) The temperature resistance depends on the material of the secondary seals used. The operating limits are defined by the PV factor which is determined for the sealing system characteristics and those of the application.

Single mechanical seal with an extremely versatile and functional design. The fact that it is attached to the shaft with screws allows this seal to be installed in a large variety of applications with differing mounting dimensions. Its structure allows secondary seals made of different materials to be used: FKM, Aflas, FFKM, FEP, NBR, HNBR and materials complying with special standards such as FDA, USP, EC, etc

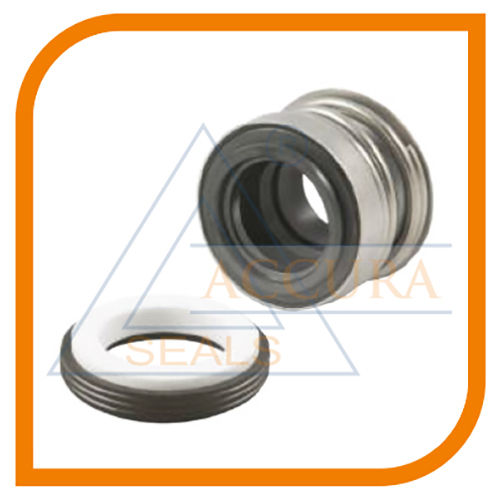

Robust Design for Industrial Durability

Built with high-grade carbon, ceramic, silicon carbide, and stainless steel, the AS40C mechanical seal is optimized for longevity and performance under demanding conditions. It ensures reliable operation in water, oil, and light chemical applications with excellent hardness and precise engineering.

Easy Installation and Versatile Media Compatibility

The AS40C single spring design enables simple and quick installation on a variety of equipment. Elastomer options (NBR, EPDM, Viton) allow adaptability to different fluids, making it ideal for multiple industrial uses.

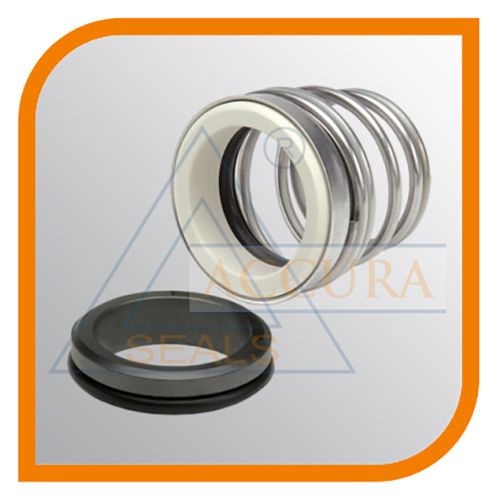

Optimal Performance Across Challenging Conditions

With a pressure rating up to 12 bar, operational speed up to 3000 RPM, and function in temperatures from -20C to 180C, this seal provides dependable sealing for water pumps, industrial pumps, and rotating machinery throughout diverse environments.

FAQs of AS40C Single mechanical seal:

Q: How is the AS40C single mechanical seal installed on industrial pumps?

A: The AS40C seal utilizes a single spring design, making installation straightforward. Simply align the seal with the shaft (12mm to 100mm diameter), secure it, and ensure the elastomer matches your specific medium. This design reduces installation time and minimizes maintenance complexity.Q: What types of media is the AS40C mechanical seal suitable for?

A: The AS40C is compatible with water, oils, mild acids, and light chemicals, thanks to its versatile elastomer optionsNBR, EPDM, and Viton. Its material construction allows for use in a wide range of industrial fluids without degradation.Q: When should I select NBR, EPDM, or Viton elastomers for this seal?

A: Choose NBR for general water and oil resistance, EPDM for better compatibility with mild acids and higher temperature water, and Viton when dealing with aggressive chemicals and higher temperatures. The selection depends on the media and temperature requirements of your application.Q: Where is the AS40C mechanical seal manufactured and supplied from?

A: This mechanical seal is manufactured, supplied, and retailed in India, ensuring regional availability and support for local industrial requirements.Q: What are the main benefits of using the AS40C single mechanical seal?

A: Key benefits include reliable sealing for various media, high durability due to premium materials, adaptability from elastomer choices, easy installation, and precision engineering (0.01 mm tolerance). These features help minimize leakage, downtime, and maintenance costs.Q: How does the AS40C perform under high pressure and speed conditions?

A: The AS40C is designed to handle pressures up to 12 bar and speeds up to 3000 RPM. Its robust build ensures stable performance in demanding operations, making it suitable for water pumps, industrial pumps, and rotating equipment exposed to rigorous workloads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Seals Category

AMS11 Seal compliant

Temperature : 0C to 250C

Material : Stainless Steel

Shape : Round

Application : Sealing for rotating equipment

Tolerance : 0.05 mm

Hardness : Medium

AMB85 Seal

Temperature : 30C to +100C

Material : Nitrile Rubber (NBR)

Shape : Round

Application : Hydraulic and Pneumatic Systems

Tolerance : 0.05 mm

Hardness : 85 Shore A

ARB05 Mechanical seal

Temperature : Up to 200C

Material : Carbon Stainless Steel

Shape : Circular

Application : Pumps

Tolerance : Standard

Hardness : High

AS15 and AS15DIN all-purpose mechanical seal

Temperature : Up to 200C

Material : Steel Ceramic and Elastomer

Shape : Circular

Application : Allpurpose mechanical seal for various industrial applications

Tolerance : High precision tolerance for durability and performance

Hardness : Medium to High

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS